Mitutoyo Products

Thread runout is the measurement of the abruptness with which the buttress thread is terminated at the triangle end of the thread. A rapid pull-out of the cutting tool results in steep slope at the end of the thread. This causes high stress at the contact point when the coupling is made-up.

Buttress runout gages ensure proper thread pullout on runout type threads. Gagemaker buttress runout gages (BR-2000 Series) have standard 1″ and 2″ point spacing. Includes one contact point (TBR) and shoes.

Calipers

TCalipers are the universal measuring tool thanks in part to their versatility. Most calipers 12”/300mm and under can perform OD, ID and step measurements and normally have a depth rod for measuring deep recesses. Calipers are available with plastic, stainless steel and carbide jaws to match your measurement requirements.

Calipers of various sizes and material are available with either vernier, dial or electronic displays. English dial calipers are normally graduated in .001” and have either .100” or .200” range per rev. Metric dial calipers are normally graduated in 0.01mm or 0.02mm and have either 1.0mm or 2.0mm range per rev.

Various styles of the Digimatic calipers (electronic displays) are offered in different versions with and without SPC outputs: standard electronic, solar powered, and an extra durable submersible option. Solar calipers never need a new battery as they work off basic indoor lighting. The Absolute Coolant Proof calipers are rated IP67 for the greatest waterproof rating available and can withstand submersion in coolant.

Gagemaker offers the following groups of Mitutoyo calipers base on display style:

- Dial Calipers

- Digimatic Calipers (Electronic/Digital)

- Vernier Calipers

| Gagemaker Model | Description | Indicator Type | Range | Resolution | Accuracy | Dial Reading | Face Color |

|---|---|---|---|---|---|---|---|

| MIT-505-671 | 0-150mm, 0.02mm Dial Caliper, 2mm/Revolution | Mechanical | 0 – 150mm | 0.02mm | ±0.03mm | 0-10-20 | Yellow |

| MIT-505-672 | 0-200mm, 0.02mm Dial Caliper, 2mm/Revolution | Mechanical | 0 – 200mm | 0.02mm | ±0.03mm | 0-10-20 | Yellow |

| MIT-505-673 | 0-300mm, 0.02mm Dial Caliper, 2mm/Revolution | Mechanical | 0 – 300mm | 0.02mm | ±0.04mm | 0-10-20 | Yellow |

| MIT-505-674 | 0-4″, .001″ Dial Caliper, .1″/Revolution, White Face | Mechanical | 0 – 4″ | .001″ | ±.001″ | 0-100 | White |

| MIT-505-675 | 0-6″, .001″ Dial Caliper, .1″/Revolution, White Face | Mechanical | 0 – 6″ | .001″ | ±.001″ | 0-100 | White |

| MIT-505-675-51 | 0-6″, .001″ Dial Caliper, .1″/Revolution, Blue Face | Mechanical | 0 – 6″ | .001″ | ±.001″ | 0-100 | Blue |

| MIT-505-675-52 | 0-6″, .001″ Dial Caliper, .1″/Revolution, Violet Face | Mechanical | 0 – 6″ | .001″ | ±.001″ | 0-100 | Violet |

| MIT-505-675-53 | 0-6″, .001″ Dial Caliper, .1″/Revolution, Green Face | Mechanical | 0 – 6″ | .001″ | ±.001″ | 0-100 | Green |

| MIT-505-675-54 | 0-6″, .001″ Dial Caliper, .1″/Revolution, Red Face | Mechanical | 0 – 6″ | .001″ | ±.001″ | 0-100 | Red |

| MIT-505-675-55 | 0-6″, .001″ Dial Caliper, .1″/Revolution, Orange Face | Mechanical | 0 – 6″ | .001″ | ±.001″ | 0-100 | Orange |

| MIT-505-675-56 | 0-6″, .001″ Dial Caliper, .1″/Revolution, Black Face | Mechanical | 0 – 6″ | .001″ | ±.001″ | 0-100 | Black |

| MIT-505-675-66 | 0-6″, .001″ Dial Caliper, .1″/Revolution, Black Face, w/Ratchet Stop | Mechanical | 0 – 6″ | .001″ | ±.001″ | 0-100 | Black |

| MIT-505-676 | 0-8″, .001″ Dial Caliper, .1″/Revolution | Mechanical | 0 – 8″ | .001″ | ±.002″ | 0-100 | White |

| MIT-505-677 | 0-12″, .001″ Dial Caliper, .1″/Revolution | Mechanical | 0 – 12″ | .001″ | ±.002″ | 0-100 | White |

| MIT-505-680 | 0-100mm, 0.01mm Dial Caliper, 1mm/Revolution | Mechanical | 0 – 100mm | 0.01mm | ±0.015mm | 0-10-20 | White |

| MIT-505-681 | 0-150mm, 0.01mm Dial Caliper, 1mm/Revolution | Mechanical | 0 – 150mm | 0.01mm | ±0.03mm | 0-10-20 | White |

| MIT-505-689 | 0-6″, .001″ Dial Caliper, .1″/Revolution, Extra Smooth | Mechanical | 0 – 6″ | .001″ | ±.001″ | 0-100 | White |

| MIT-505-690 | 0-8″, .001″ Dial Caliper, .1″/Revolution, Extra Smooth | Mechanical | 0 – 8″ | .001″ | ±.002″ | 0-100 | White |

| MIT-505-708 | 0-6″, .001″ Dial Caliper, .1″/Revolution, Carbide OD Jaws | Mechanical | 0 – 6″ | .001″ | ±.001″ | 0-100 | White |

| MIT-505-709 | 0-8″, .001″ Dial Caliper, .1″/Revolution, White Face, Carbide OD Jaws | Mechanical | 0 – 8″ | .001″ | ±.002″ | 0-100 | White |

| MIT-505-710 | 0-12″, .001″ Dial Caliper, .1″/Revolution, White Face, Carbide OD | Mechanical | 0 – 12″ | .001″ | ±.002″ | 0-100 | White |

| MIT-505-711 | 0-150mm, 0.02mm Dial Caliper, 2mm/Revolution, Carbide OD and ID Jaws | Mechanical | 0 – 6″ | 0.02mm | ±0.03mm | 0-10-20 | White |

| MIT-505-712 | 0-6″, .001″ Dial Caliper, .1″/Revolution, Carbide OD and ID Jaws | Mechanical | 0 – 6″ | .001″ | ±.001″ | 0-100 | White |

| MIT-505-713 | 0-8″, .001″ Dial Caliper, .1″/Revolution, White Face, Carbide OD/ID Jaws | Mechanical | 0 – 8″ | .001″ | ±.002″ | 0-100 | White |

| MIT-505-714 | 0-12″, .001″ Dial Caliper, .1″/Revolution, White Face, Carbide OD/ID Jaws | Mechanical | 0 – 12″ | .001″ | ±.002″ | 0-100 | White |

| MIT-505-716 | 0-4″, .001″ Dial Caliper, .2″/Revolution, White Face | Mechanical | 0 – 4″ | .001″ | ±.001″ | 0-100-200 | White |

| MIT-505-717 | 0-6″, .001″ Dial Caliper, .2″/Revolution, White Face | Mechanical | 0 – 6″ | .001″ | ±.001″ | 0-100-200 | White |

| MIT-505-718 | 0-6″, .001″ Dial Caliper, .2″/Revolution, Carbide OD Jaws | Mechanical | 0 – 6″ | .001″ | ±.001″ | 0-100-200 | White |

| MIT-505-719 | 0-8″, .001″ Dial Caliper, .2″/Revolution, White Face | Mechanical | 0 – 8″ | .001″ | ±.002″ | 0-100-200 | White |

| MIT-505-720 | 0-12″, .001″ Dial Caliper, .2″/Revolution, White Face | Mechanical | 0 – 12″ | .001″ | ±.002″ | 0-100-200 | White |

| Gagemaker Model | Product Type | Description | Indicator Type | Range | Resolution | Accuracy | Depth Rod Shape | SPC Output |

|---|---|---|---|---|---|---|---|---|

| MIT-500-151-20 | Caliper | 0-150mm, 0.01mm ABSOLUTE AOS Digimatic Caliper, With SPC Data Output | Digimatic | 0 – 150mm | 0.01mm | ±0.02mm | – | No |

| MIT-500-152-30 | Caliper | 0-200mm, 0.01mm ABSOLUTE AOS Digimatic Caliper, With SPC Data Output | Digimatic | 0 – 200mm | 0.01mm | ±0.02mm | – | No |

| MIT-500-153 | Caliper | 0-300mm, 0.01mm ABSOLUTE Digimatic Caliper, With SPC Data Output | Digimatic | 0 – 300mm | 0.01mm | ±0.03mm | – | No |

| MIT-500-159-30 | Caliper | 0-6″/150mm, .0005″/0.01mm ABSOLUTE AOS Digimatic Caliper, No Output, Carbide OD Jaws | Digimatic | 0 – 6″/ 0 – 150mm | .0005″/0.01mm | ±.001″ | – | No |

| MIT-500-160-30 | Caliper | 0-6″/150mm, .0005″/0.01mm ABSOLUTE AOS Digimatic Caliper, No Output, Carbide OD/ID Jaws | Digimatic | 0 – 6″/ 0 – 150mm | .0005″/0.01mm | ±.001″ | – | No |

| MIT-500-163-30 | Caliper | 0-8″/200mm, .0005″/0.01mm ABSOLUTE AOS Digimatic Caliper, No Output, Carbide OD Jaws | Digimatic | 0 – 8″/ 0 – 200mm | .0005″/0.01mm | ±.001″ | – | No |

| MIT-500-164-30 | Caliper | 0-8″/200mm, .0005″/0.01mm ABSOLUTE AOS Digimatic Caliper, No Output, Carbide OD/ID Jaws | Digimatic | 0 – 8″/0 – 200mm | .0005″/0.01mm | ±.001″ | – | No |

| MIT-500-165 | Caliper | 0-12″/300mm, .0005″/0.01mm ABSOLUTE Digimatic Caliper, No Output, Carbide OD Jaws | Digimatic | 0 – 12″/ 0 – 300mm | .0005″/0.01mm | ±.0015″ | – | No |

| MIT-500-166 | Caliper | 0-12″/300mm, .0005″/0.01mm ABSOLUTE Digimatic Caliper, No Output, Carbide OD/ID Jaws | Digimatic | 0 – 12″/ 0 – 300mm | .0005″/0.01mm | ±.0015″ | – | No |

| MIT-500-167 | Caliper | 0-12″/300mm, .0005″/0.01mm ABSOLUTE Digimatic Caliper, With SPC Data Output, Carbide OD Jaws | Digimatic | 0 – 12″/ 0 – 300mm | .0005″/0.01mm | ±.0015″ | – | No |

| MIT-500-168 | Caliper | 0-12″/300mm, .0005″/0.01mm ABSOLUTE Digimatic Caliper, With SPC Data Output, Carbide OD/ID Jaws | Digimatic | 0 – 12″/0 – 300mm | .0005″/0.01mm | ±.0015″ | – | Yes |

| MIT-500-170-30 | Caliper | 0-4″/100mm, .0005″/0.01mm ABSOLUTE AOS Digimatic Caliper, With SPC Data Output, .075″ Round Depth Bar | Digimatic | 0 – 4″/0 – 100mm | .0005″/0.01mm | ±.001″ | – | Yes |

| MIT-500-171-30 | Caliper | 0-6″/150mm, .0005″/0.01mm ABSOLUTE AOS Digimatic Caliper, With SPC Data Output | Digimatic | 0 – 6″/0 – 150mm | .0005″/0.01mm | ±.001″ | – | Yes |

| MIT-500-172-30 | Caliper | 0-8″/200mm, .0005″/0.01mm ABSOLUTE AOS Digimatic Caliper, With SPC Data Output | Digimatic | 0 – 8″/0 – 200mm | .0005″/0.01mm | ±.001″ | – | Yes |

| MIT-500-173 | Caliper | 0-12″/300mm, .0005″/0.01mm ABSOLUTE Digimatic Caliper, With SPC Data Output | Digimatic | 0 – 12″/0 – 300mm | .0005″/0.01mm | ±.0015″ | – | Yes |

| MIT-500-174-30 | Caliper | 0-6″/150mm, .0005″/0.01mm ABSOLUTE AOS Digimatic Caliper, With SPC Data Output, Carbide OD Jaws | Digimatic | 0 – 6″/ 0 – 150mm | .0005″/0.01mm | ±.001″ | – | Yes |

| MIT-500-175-30 | Caliper | 0-6″/150mm, .0005″/0.01mm ABSOLUTE AOS Digimatic Caliper, With SPC Data Output, Carbide OD/ID Jaws | Digimatic | 0 – 6″/0 – 150mm | .0005″/0.01mm | ±.001″ | Rectangular | Yes |

| MIT-500-176-30 | Caliper | 0-8″/200mm, .0005″/0.01mm ABSOLUTE AOS Digimatic Caliper, With SPC Data Output, Carbide OD Jaws | Digimatic | 0 – 8″/ 0 – 200mm | .0005″/0.01mm | ±.001″ | Rectangular | Yes |

| MIT-500-177-30 | Caliper | 0-8″/200mm, .0005″/0.01mm ABSOLUTE AOS Digimatic Caliper, With SPC Data Output, Carbide OD/ID Jaws | Digimatic | 0 – 8″/0 – 200mm | .0005″/0.01mm | ±.001″ | Rectangular | Yes |

| MIT-500-178-30 | Caliper | 0-6″/150mm, .0005″/0.01mm ABSOLUTE AOS Digimatic Caliper, With SPC Data Output, .075″ Round Depth Bar | Digimatic | 0 – 6″/ 0 – 150mm | .0005″/0.01mm | ±.001″ | Rectangular | Yes |

| MIT-500-193 | Caliper | 0-12″/300mm, .0005″/0.01mm ABSOLUTE Digimatic Caliper, No Output | Digimatic | 0 – 12″/0 – 300mm | .0005″/0.01mm | ±.0015″ | Rectangular | No |

| MIT-500-195-30 | Caliper | 0-4″/100mm, .0005″/0.01mm ABSOLUTE AOS Digimatic Caliper, No Output, .075″ Round Depth Bar | Digimatic | 0 – 4″/0 – 100mm | .0005″/0.01mm | ±.001″ | Round | No |

| MIT-500-196-30 | Caliper | 0-6″/150mm, .0005″/0.01mm ABSOLUTE AOS Digimatic Caliper, No Output | Digimatic | 0 – 6″/0 – 150mm | .0005″/0.01mm | ±.001″ | Rectangular | No |

| MIT-500-197-30 | Caliper | 0-8″/200mm, .0005″/0.01mm ABSOLUTE AOS Digimatic Caliper, No Output | Digimatic | 0 – 8″/0 – 200mm | .0005″/0.01mm | ±.001″ | Rectangular | No |

| MIT-500-505-10 | Caliper | 0-18″/450mm, .0005″/0.01mm ABSOLUTE Digimatic Caliper, With SPC Data Output, No Thumb Roller | Digimatic | 0 – 18″/0 – 450mm | .0005″/0.01mm | ±.002″ | – | Yes |

| MIT-500-506-10 | Caliper | 0-24″/600mm, .0005″/0.01mm ABSOLUTE Digimatic Caliper, With SPC Data Output, No Thumb Roller | Digimatic | 0 – 24″/0 – 600mm | .0005″/0.01mm | ±.002″ | – | Yes |

| MIT-500-507-10 | Caliper | 0-40″/1000mm, .0005″/0.01mm ABSOLUTE Digimatic Caliper, With SPC Data Output, No Thumb Roller | Digimatic | 0 – 40/0 – 1000mm | .0005″/0.01mm | ±.003″ | – | Yes |

| MIT-500-702-10 | Caliper | 0-150mm, .01mm, IP67 ABSOLUTE Digimatic Caliper, With SPC Data Output | Digimatic | 0 – 150mm | 0.01mm | ±0.02mm | – | No |

| MIT-500-731-10 | Caliper | 0-6″/150mm, .0005″/0.01mm, IP67 ABSOLUTE Digimatic Caliper, No Output, Carbide OD Jaws | Digimatic | 0 – 6″/0 – 150mm | .0005″/0.01mm | ±.001″ | – | No |

| MIT-500-732-10 | Caliper | 0-8″/200mm, .0005″/0.01mm, IP67 ABSOLUTE Digimatic Caliper, No Output, Carbide OD Jaws | Digimatic | 0 – 8″/0 – 200mm | .0005″/0.01mm | ±.001″ | – | No |

| Gagemaker Model | Product Type | Description | Indicator Units | Indicator Type | Range | Resolution | Accuracy |

|---|---|---|---|---|---|---|---|

| MIT-530-104 | Caliper | 0-150mm/0-6”, 0.05mm and 1/128”, Vernier Caliper, Dual Scale | Inch/Metric | Mechanical | 0 – 6”/0 – 150mm | 1/128” | ±0.05mm |

| MIT-530-105 | Caliper | 0-6”, .001” and 1/128”, Vernier Caliper, Dual Scale | Inch | Mechanical | 0 – 6” | .001”; 1/128” | ±.0015” |

| MIT-530-116 | Caliper | 0-8”, .001” and 1/128”, Vernier Caliper, Dual Scale | – | Mechanical | 0 – 8” | .001”; 1/128” | ±.0015” |

| MIT-530-118 | Caliper | 0-200mm/0-8”, 0.02mm/.001”, Vernier Caliper, High Accuracy, Dual Scale | Inch/Metric | Mechanical | 0 – 8”/0 – 200mm | .001” | ±0.03mm |

| MIT-530-119 | Caliper | 0-300mm/0-1”, 0.02mm/.001”, Vernier Caliper, High Accuracy, Dual Scale | Inch/Metric | Mechanical | 0 – 12”/0 – 300mm | .001” | ±0.04mm |

| MIT-530-312 | Caliper | 0-150mm/0-6”, 0.02mm/.001”, Vernier Caliper, High Accuracy, Dual Scale | Inch/Metric | Mechanical | 0 – 6”/0 – 150mm | .001” | ±0.03mm |

| MIT-531-128 | Caliper | 0-150mm/0-6”, .02mm/.001”, Vernier Caliper, Thumb Clamp, High Accuracy, Dual Scale | Inch/Metric | Mechanical | 0 – 6”/0 – 150mm | .001” | ±0.03mm |

| MIT-531-129 | Caliper | 0-200mm/0-8”, .02mm/.001”, Vernier Caliper, Thumb Clamp, High Accuracy, Dual Scale | Inch/Metric | Mechanical | 0 – 8”/0 – 200mm | .001” | ±0.03mm |

| MIT-527-103 | Depth Gage | 0-300mm, 0.02mm Vernier Depth Gage, With Fine Adjustment | – | Mechanical | 0 – 300mm | 0.02mm | ±0.04mm |

| MIT-527-311-50 | Depth Gage | 6”,, .001” Dial Depth Gage, With Fine Adjustment | – | Mechanical | 0 – 6” | .001” | ±.001” |

Form Measurement

A small, lightweight, and extremely easy to use surface roughness measurement instrument that lets you view surface roughness waveforms right on a color LCD screen.

The popular Surftest SJ-210 is a user-friendly surface roughness measurement instrument designed as a handheld tool that can be carried with you and used on-site. The SJ-Series testers work great with the Mitutoyo Height gages.

| Gagemaker Model | Product Group | Product Type | Description | Indicator Type | Range | Resolution | Accuracy | Output Type | Length | Width |

|---|---|---|---|---|---|---|---|---|---|---|

| MIT-12AAA210 | Surftest Optional Accessory | Extension Rod | 1.97″/50mm Detector Extension Rod, For SJ-210 and SJ-310 Detectors, Not for Transverse Type Models, Only One Extention Rod Can be Used | Mechanical | – | – | – | – | 1.97″/50mm | – |

| MIT-12AAA218 | Surftest Optional Accessory | Nosepiece | Nosepiece For Cylindrical Surfaces, For SJ-210 and SJ-310 Detectors, Not for Transverse Type Models, 30mm Diameter or Smaller Workpiece | Mechanical | – | – | – | – | – | – |

| MIT-12AAA220 | Surftest Optional Accessory | Magnetic Stand Adapter | Magnetic Stand Adapter, .375″/9.5mm Diameter, for SJ-210 and SJ-310 Surface Roughness Tester | Mechanical | – | – | – | – | .37″/9.5mm | – |

| MIT-12AAA222 | Surftest Optional Accessory | Height Gage Adapter | Height Gage Adapter, For SJ-210 and SJ-310 Surface Roughness Tester, 9mm x 9mm | Mechanical | – | – | – | – | .35″/9mm | 9mm |

| MIT-12AAA233 | Surftest Optional Accessory | Height Gage Adapter | Height Gage Adapter, For SJ-210 and SJ-310 Surface Roughness Tester, .25″ x .5″ | Mechanical | – | – | – | – | .25″ | .50″ |

| MIT-12BAA303 | Surftest Optional Accessory | Cable | Extension Cable, Drive Unit to Display Connection, For SJ-210 and SJ-310 Surface Roughness Tester, 40″/1m, Only One Cable Can be Used | Mechanical | – | – | – | – | 40″/1m | – |

| MIT-178-029 | Column Stand for SJ200/300 | Column Stand | Manual Column Stand, 10″/250mm Vertical Travel, For SJ-210 and SJ-310 Surface Roughness Tester, Granite Base | – | – | – | – | – | – | – |

| MIT-178-039 | Granite Base 250mm Vertical Travel | Column Stand | Manual Column Stand, 10″/250mm Vertical Travel, For SJ-410 Surface Roughness Tester, Granite Base | – | – | – | – | – | – | – |

| MIT-178-230-2 | Standard Drive Unit | Drive Unit | Standard Type Drive Unit, For SJ-210 and SJ-310 Surface Roughness Tester | – | – | – | – | – | – | – |

| MIT-178-235 | Standard Drive Unit | Drive Unit | Retractable Type Drive Unit, For SJ-210 and SJ-310 Surface Roughness Tester | – | – | – | – | – | – | – |

| MIT-178-296 | SJ210/310 Detector | Detector | .75mN, 60 degree 2 Micron Stylus Tip, Replacement Low-Force Detector for SJ-210 and SJ-310 Surface Roughness Tester Standard and Retractable Drive Unit Models | – | – | – | – | – | – | – |

| MIT-178-390 | Standard Detector for Standard/Retractable drive unit | Detector | 4mN, 90 degree 5 Micron Stylus Tip, Replacement Detector for SJ-210 and SJ-310 Surface Roughness Tester Standard and Retractable Drive Unit Models | – | – | – | – | – | – | – |

| MIT-178-391 | Standard Detector for Standard/Retractable drive unit | Detector | 4mN, 90 degree 10 Micron Stylus Tip, Replacement Detector for SJ-410 and SJ-310 Surface Roughness Tester Standard and Retractable Drive Unit Models | – | – | – | – | – | – | – |

| MIT-178-392 | Small Hole Detector for SJ-210/310 | Detector | 4mN, 90 degree 5 Micron Stylus Tip, Replacement Small Hole Detector for SJ-410 and SJ-310 Surface Roughness Tester Standard, Retractable and Transverse Drive Unit Models, 4.5mm Diameter Minimum Hole Size | – | – | – | – | – | – | – |

| MIT-178-393 | Extra Small Hole Detector for SJ-210/310 | Detector | 4mN, 90 degree 5 Micron Stylus Tip, Replacement Extra-Small Hole Detector for SJ-410 and SJ-310 Surface Roughness Tester Standard, Retractable and Transverse Drive Unit Models, 2.8mm Diameter Minimum Hole Size | – | – | – | – | – | – | – |

| MIT-178-394 | Deep Groove Detector for Transverse tracing drive unit | Detector | 4mN, 90 degree 5 Micron Stylus Tip, Replacement Deep Groove Detector for SJ-410 and SJ-310 Surface Roughness Tester Standard and Retractable Drive Unit Models, Not for Transverse Type Models | – | – | – | – | – | – | – |

| MIT-178-395 | Low force detector for SJ-210/310 | Detector | .75mN, 90 degree 2 Micron Stylus Tip, Replacement Low-Force Detector for SJ-210 and SJ-310 Surface Roughness Tester Standard and Retractable Drive Unit Models | – | – | – | – | – | – | – |

| MIT-178-396-2 | Low force detector for SV-3000CNCw/QVPII | Detector | .75mN, 60 degree 2 Micron Stylus Tip, Replacement Low-Force Detector for SJ-410 Surface Roughness Tester Models | – | – | – | – | – | – | – |

| MIT-178-397 | Detector for SJ-401, 4mN | Detector | 4mN, 90 degree 5 Micron Stylus Tip, Replacement Detector for SJ-410 Surface Roughness Tester Models | – | – | – | – | – | – | – |

| MIT-178-397-2 | Detector 4MN/90 | Detector | 4mN, 90 degree 5 Micron Stylus Tip, Replacement Detector for SJ-410 Surface Roughness Tester Models, Reinforced Spring Clip, Does Not”clude Skidded Nose Piece | – | – | – | – | – | – | – |

| MIT-178-561-01A | Standard Type SJ-210 with 0.75mN Detector | Portable Surface roughness Tester | SJ-210 Portable Surface Roughness Tester, Skidded, .7″/17.5mm Evaluation Range, .75mN Measuring Force, 60 degree 2 Micron Stylus Tip, Color Built-In Display Unit, USB/RS-232C Output | Digital | .7 In/17.5mm | Variable | Special | USB/RS-232C | – | – |

| MIT-178-561-02A | Standard Type SJ-210 with 4mN Detector | Portable Surface roughness Tester | SJ-210 Portable Surface Roughness Tester, Skidded, .7″/17.5mm Evaluation Range, 4mN Measuring Force, 90 degree 5 Micron Stylus Tip, Color Built-In Display Unit, USB/RS-232C Output | Digital | .7 In/17.5mm | Variable | Special | USB/RS-232C | – | – |

| MIT-178-563-01A | 0.75mN Type Detector | Portable Surface roughness Tester | SJ-210 Portable Surface Roughness Tester, Retractable Detector, Skidded, .7″/17.5mm Evaluation Range, .75mN Measuring Force, 60 degree 2 Micron Stylus Tip, Color Built-In Display Unit, USB/RS-232C Output | Digital | .7 In/17.5mm | Variable | Special | USB/RS-232C | – | – |

| MIT-178-563-02A | 4mN Type Detector | Portable Surface roughness Tester | SJ-210 Portable Surface Roughness Tester, Retractable Detector, Skidded, .7″/17.5mm Evaluation Range, 4mN Measuring Force, 90 degree 5 Micron Stylus Tip, Color Built-In Display Unit, USB/RS-232C Output | Digital | .7 In/17.5mm | Variable | Special | USB/RS-232C | – | – |

| MIT-178-571-01A | 0.75mN Type Detector | Portable Surface roughness Tester | SJ-310 Portable Surface Roughness Tester, Skidded, .7″/17.5mm Evaluation Range, .75mN Measuring Force, 60 degree 2 Micron Stylus Tip, Color External Display Unit, Printer, USB/RS-232C Output | Digital | .7 In/17.5mm | Variable | Special | USB/RS-232C | – | – |

| MIT-178-571-02A | 4mN Type Detector | Portable Surface roughness Tester | SJ-310 Portable Surface Roughness Tester, Skidded, .7″/17.5mm Evaluation Range, 4mN Measuring Force, 90 degree 5 Micron Stylus Tip, Color External Display Unit, Printer, USB/RS-232C Output | Digital | .7 In/17.5mm | Variable | Special | USB/RS-232C | – | – |

| MIT-178-581-01A | 0.75mN Type Detector | Portable Surface roughness Tester | SJ-411 Portable Surface Roughness Tester, Skidless, 1″/25mm Evaluation Range, .75mN Measuring Force, 60 degree 2 Micron Stylus Tip, Color External Display Unit, Printer, USB/RS-232C Output | Digital | 1 In/25mm | Variable | Special | USB/RS-232C | – | – |

| MIT-178-581-02A | 4mN Type Detector | Portable Surface roughness Tester | SJ-411 Portable Surface Roughness Tester, Skidless, 1″/25mm Evaluation Range, 4mN Measuring Force, 90 degree 5 Micron Stylus Tip, Color External Display Unit, Printer, USB/RS-232C Output | Digital | 1 In/25mm | Variable | Special | USB/RS-232C | – | – |

| MIT-178-601 | Roughness Specimen | Roughness Speciman | Roughness Specimen, For Surface Roughness Tester, Metric | – | – | – | – | – | – | – |

| MIT-178-602 | Roughness Specimen | Roughness Speciman | Roughness Specimen, For Surface Roughness Tester, Inch/Metric | – | – | – | – | – | – | – |

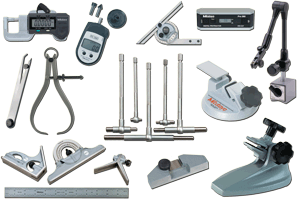

Gages

Mitutoyo offers a wide range of various gages found or needed in most shops and labs.Mechanical height gages have three basic types: dial, vernier, and digital counter. Dial height gates are usually only available under 12” and are easily stored. Vernier gages range from 6” to 6’ with one or two scales. Digital counter gages decrease part layout time and are easier to read.

Digimatic or electronic height gages are broken into three groups. Group 1 are similar to mechanical gages in accuracy but have additional features like inch/metric conversion and data output. Group 2 includes all features of Group 1 but with higher accuracies and more features, like tolerance settings, ID/OD measurement, etc. Generally, Group 3 has even higher accuracies coupled with all of the features of the first two groups plus more sophisticated features, like a computer interface or motorized probes.

Other reference gages, especially gauge blocks, are also useful, popular shop instruments. Mitutoyo gauge blocks are divided into three levels: lab, inspection, and shop. Lab grade blocks must be kept under controlled environmental conditions and are manufactured with the highest precision available.

Inspection grade blocks are the Goldilocks blocks. They don’t need a controlled environment but they can’t be kept and knocked around on the shop floor. They’re just right in the middle providing the perfect fit for most at the best value in cost versus high accuracy.

Shop grade blocks are the basic blocks found on a shop floor and are expected to endure quite a bit of wear and tear. While shop blocks don’t need a controlled environment or have the tightest tolerances, they are made of the finest materials and up to Mitutoyo’s strict standards of quality providing the basic accuracy a shop floor needs.

Gagemaker offers these Mitutoyo Gages.

- Dial Digimatic Height Gages

- Linear Height Gages

- Mechanical Height Gages

- Reference Gages/Gauge Blocks

| Gagemaker Model | Product Type | Description | Indicator Type | Range | Resolution | Accuracy | SPC output? |

|---|---|---|---|---|---|---|---|

| MIT-192-630-10 | Height Gage | 0-12″/300mm, .0005″/.0002″/0.01mm/0.005mm, Standard Type Digimatic Height Gage, With SPC Output | Digimatic | 0 – 12″/0 – 300mm | .0005″/0.01mm; .0002″/0.005mm | ±001″ | Yes |

| MIT-192-631-10 | Height Gage | 0-18″/450mm, .0005″/.0002″/0.01mm/0.005mm, Standard Type Digimatic Height Gage, With SPC Output | Digimatic | 0 – 18″/0 – 450mm | .0005″/0.01mm; .0002″/0.005mm | ±002″ | Yes |

| MIT-192-632-10 | Height Gage | 0-24″/600mm, .0005″/.0002″/0.01mm/0.005mm, Standard Type Digimatic Height Gage, With SPC Output | Digimatic | 0 – 24″/0 – 600mm | .0005″/0.01mm; .0002″/0.005mm | ±002″ | Yes |

| MIT-192-633-10 | Height Gage | 0-40″/1000mm, .0005″/.0002″/0.01mm/0.005mm, Standard Type Digimatic Height Gage, With SPC Output | Digimatic | 0-40″/0 – 1000mm | .0005″/0.01mm; .0002″/0.005mm | ±003″ | Yes |

| MIT-192-670-10 | Height Gage | 0-12″/300mm, .0005″/.0002″/0.01mm/0.005mm, Multi-Function Type Digimatic Height Gage, With SPC Output | Digimatic | 0-12″/0 – 300mm | .0005″/0.01mm; .0002″/0.005mm | ±.001″ | Yes |

| MIT-192-671-10 | Height Gage | 0-18″/450mm, .0005″/.0002″/0.01mm/0.005mm, Multi-Function Type Digimatic Height Gage, With SPC Output | Digimatic | 0-18″/0 – 450mm | .0005″/0.01mm; .0002″/0.005mm | ±0015″ | Yes |

| MIT-192-672-10 | Height Gage | 0-24″/600mm, .0005″/.0002″/0.01mm/0.005mm, Multi-Function Type Digimatic Height Gage, With SPC Output | Digimatic | 0 – 24″/0 – 600mm | .0005″/0.01mm; .0002″/0.005mm | ±0015″ | Yes |

| MIT-570-244 | Height Gage | 0-8″/200mm, .0005″/0.01mm, ABSOLUTE Digimatic Height Gage, With Carbide Tipped Scriber, With SPC Output | Digimatic | 0 – 8″/0 – 200mm | .0005″/.01mm | ±.001″ | Yes |

| MIT-570-312 | Height Gage | 0-12″/300mm, .0005″/0.01mm, ABSOLUTE Digimatic Height Gage, With Carbide Tipped Scriber, With SPC Output | Digimatic | 0 – 12″/0 – 300mm | .0005″/.01mm | ±.0015″ | Yes |

| MIT-570-313 | Height Gage | 0-18″/450mm, .0005″/0.01mm, ABSOLUTE Digimatic Height Gage, With Carbide Tipped Scriber, With SPC Output | Digimatic | 0 – 18″/0 – 450mm | .0005″/.01mm | ±.002″ | Yes |

| MIT-570-314 | Height Gage | 0-24″/600mm, .0005″/0.01mm, ABSOLUTE Digimatic Height Gage, With Carbide Tipped Scriber, With SPC Output | Digimatic | 0 – 24″/0 – 600mm | .0005″/.01mm | ±.002″ | Yes |

| MIT-905201 | Scriber | 150mm Length Carbide Tipped Height Gage Scriber for 192/570 Series Inch Height Gage Models | NA | NA | NA | NA | NA |

| Gagemaker Model | Product Type | Description | Indicator Type | Range | Resolution | Accuracy | Output Type |

|---|---|---|---|---|---|---|---|

| MIT-518-231 | Linear Height Gage | 0-14″/0-350mm, .00005″/.0001″/.0002″/0.001mm/0.005mm, QM-Height High Precision ABSOLUTE Digimatic Height Gage, With SPC Data Output | – | 0 – 14″/0 – 350mm | .00005”, .0001”, .0002”/0.001mm, 0.005mm | ±(2.4+2.1L/600)μm | SPC |

| MIT-518-233 | Linear Height Gage | 0-24″/0-600mm, .00005″/.0001″/.0002″/0.001mm/0.005mm, QM-Height High Precision ABSOLUTE Digimatic Height Gage, With SPC Data Output | – | 0 – 24″/0 – 600mm | .00005”, .0001”, .0002”/0.001mm, 0.005mm | ±(2.4+2.1L/600)μm | SPC |

| MIT-518-351A-21 | Linear Height Gage | 0-38 In (24 In stroke)/0-972mm (600mm stroke), .000001″/.00001″/.0001″/.001″/0.0001mm/0.001mm/0.01mm/0.1mm, LH-600E High Precision Digimatic Height Gage, With USB/RS-232C Data Output | Digimatic | 0 – 38″/0 – 972mm | .000001”/.00001”/.0001”/.001”, 0.0001mm/0.001mm/0.01mm/0.1mm | .000043 + (.000024 x L*/24)” / (1.1 + 0.6L**/600)μm | USB/RS-232C |

| MIT-64PKA094A | Linear Height Gage | 0-14″/0-350mm, .00005″/.0001″/.0002″/0.001mm/0.005mm, QM-Height High Precision ABSOLUTE Digimatic Height Gage, With 120V AC Adapter, With SPC Data Output | – | 0 – 14″/0 – 350mm | .00005”, .0001”, .0002”/0.001mm, 0.005mm | ±(2.4+2.1L/600)μm | SPC |

| MIT-64PKA095A | Linear Height Gage | 0-24″/0-600mm, .00005″/.0001″/.0002″/0.001mm/0.005mm, QM-Height High Precision ABSOLUTE Digimatic Height Gage, With 120V AC Adapter, With SPC Data Output | – | 0 – 24″/0 – 600mm | .00005”, .0001”, .0002”/0.001mm, 0.005mm | ±(2.4+2.1L/600)μm | SPC |

| MIT-957261 | Linear Height Gage Probe | 2mm Diameter, Height Gage Ball Probe for QM-Height and LH-600E Digimatic Height Gages | – | – | – | – | – |

| Gagemaker Model | Product Type | Description | Indicator Type | Range | Resolution | Accuracy | Length | Dial Reading | Dial Face Color |

|---|---|---|---|---|---|---|---|---|---|

| MIT-900581 | Center Master | .04-1.5″/ 1-38mm Diameter, Height Gage Center Master, with Inch Type Hold Bar | – | – | – | – | – | – | – |

| MIT-900878 | Depth Attachment | .217″ Minimum Diameter, 2.95″ Maximum Reach, Height Gage Depth Gage Attachment, with Inch Type Hold Bar | – | – | – | – | 2.95″ | – | – |

| MIT-192-150 | Height Gage | 0-12″, .001″, Dial Height Gage, with Dual Digit Counters, with Carbide Tipped Scriber | Mechanical | 0 – 12″ | .001″ | ±.0015″ | – | 0-100 | White |

| MIT-192-152 | Height Gage | 0-24″, .001″, Dial Height Gage, with Dual Digit Counters, with Carbide Tipped Scriber | Mechanical | 0 – 24″ | .001″ | ±.002″ | – | 0-100 | White |

| MIT-900173 | Scriber | 47mm Length Carbide-Tipped Height Gage Scriber for 570/506/509 Series Inch Height Gage Models | – | – | – | – | 47mm | – | – |

| MIT-900258 | Scriber | 60mm Length Carbide-Tipped Height Gage Scriber for 192/570/574 Series Inch Height Gage Models | – | – | – | – | 60mm | – | – |

| Gagemaker Model | Product Type | Description | Rectangular/Square | Length | Range | Blocks Per Set |

|---|---|---|---|---|---|---|

| MIT-611105-531 | Gage Block | .05″, Rectangular Steel Gage Block, ASME 0, Supplied with a Certificate of Inspection | Rectangular | .05″ | – | – |

| MIT-611105-541 | Gage Block | .05″, Rectangular, Steel, Gage Block, AS-1, Supplied with a Certificate of Inspection | Rectangular | .05″ | – | – |

| MIT-611106-531 | Gage Block | .06″, Rectangular, Steel, Gage Block, ASME 0, Supplied with a Certificate of Inspection | Rectangular | .06″ | – | – |

| MIT-611115-531 | Gage Block | .15″, Rectangular, Steel, Gage Block, ASME 0, Supplied with a Certificate of Inspection | Rectangular | .15″ | – | – |

| MIT-611121-531 | Gage Block | .1001″, Rectangular, Steel, Gage Block, ASME 0, Supplied with a Certificate of Inspection | Rectangular | 0.1001″ | – | – |

| MIT-611135-531 | Gage Block | .10005″, Rectangular, Steel, Gage Block, ASME 0, Supplied with a Certificate of Inspection | Rectangular | 0.10005″ | – | – |

| MIT-611141-531 | Gage Block | .101″, Rectangular, Steel, Gage Block, ASME 0, Supplied with a Certificate of Inspection | Rectangular | 0.101″ | – | – |

| MIT-611160-531 | Gage Block | .120″, Rectangular, Steel, Gage Block, ASME 0, Supplied with a Certificate of Inspection | Rectangular | 0.12″ | – | – |

| MIT-611165-531 | Gage Block | .125″, Rectangular, Steel, Gage Block, ASME 0, Supplied with a Certificate of Inspection | Rectangular | 0.125″ | – | – |

| MIT-611165-541 | Gage Block | .125″, Rectangular, Steel, Gage Block, AS-1, Supplied with a Certificate of Inspection | Rectangular | 0.125″ | – | – |

| MIT-611170-531 | Gage Block | .130″, Rectangular, Steel, Gage Block, ASME 0, Supplied with a Certificate of Inspection | Rectangular | 0.13″ | – | – |

| MIT-611180-531 | Gage Block | .140″, Rectangular, Steel, Gage Block, ASME 0, Supplied with a Certificate of Inspection | Rectangular | 0.14″ | – | – |

| MIT-611191-531 | Gage Block | .100″, Rectangular, Steel, Gage Block, ASME 0, Supplied with a Certificate of Inspection | Rectangular | 0.1″ | – | – |

| MIT-611191-541 | Gage Block | .100″, Rectangular, Steel, Gage Block, AS-1, Supplied with a Certificate of Inspection | Rectangular | 0.1″ | – | – |

| MIT-611192-531 | Gage Block | .20″, Rectangular, Steel, Gage Block, ASME 0, Supplied with a Certificate of Inspection | Rectangular | 0.2″ | – | – |

| MIT-611192-541 | Gage Block | .20″, Rectangular, Steel, Gage Block, AS-1, Supplied with a Certificate of Inspection | Rectangular | 0.2″ | – | – |

| MIT-611193-531 | Gage Block | .30″, Rectangular, Steel, Gage Block, ASME 0, Supplied with a Certificate of Inspection | Rectangular | 0.3″ | – | – |

| MIT-611194-531 | Gage Block | .40″, Rectangular, Steel, Gage Block, ASME 0, Supplied with a Certificate of Inspection | Rectangular | 0.4″ | – | – |

| MIT-611195-531 | Gage Block | .50″, Rectangular, Steel, Gage Block, ASME 0, Supplied with a Certificate of Inspection | Rectangular | 0.5″ | – | – |

| MIT-611195-541 | Gage Block | .50″, Rectangular, Steel, Gage Block, AS-1, Supplied with a Certificate of Inspection | Rectangular | 0.5″ | – | – |

| MIT-611196-531 | Gage Block | .60″, Rectangular, Steel, Gage Block, ASME 0, Supplied with a Certificate of Inspection | Rectangular | 0.6″ | – | – |

| MIT-611201-531 | Gage Block | 1.0″, Rectangular, Steel, Gage Block, ASME 0, Supplied with a Certificate of Inspection | Rectangular | 1″ | – | – |

| MIT-611201-541 | Gage Block | 1.0″, Rectangular, Steel, Gage Block, AS-1, Supplied with a Certificate of Inspection | Rectangular | 1″ | – | – |

| MIT-611202-531 | Gage Block | 2.0″, Rectangular, Steel, Gage Block, ASME 0, Supplied with a Certificate of Inspection | Rectangular | 2″ | – | – |

| MIT-611203-531 | Gage Block | 3.0″, Rectangular, Steel, Gage Block, ASME 0, Supplied with a Certificate of Inspection | Rectangular | 3″ | – | – |

| MIT-611204-531 | Gage Block | 4.0″, Rectangular, Steel, Gage Block, ASME 0, Supplied with a Certificate of Inspection | Rectangular | 4″ | – | – |

| MIT-611212-531 | Gage Block | .25″, Rectangular, Steel, Gage Block, ASME 0, Supplied with a Certificate of Inspection | Rectangular | 0.25″ | – | – |

| MIT-611212-541 | Gage Block | .25″, Rectangular, Steel, Gage Block, AS-1, Supplied with a Certificate of Inspection | Rectangular | 0.25″ | – | – |

| MIT-611214-531 | Gage Block | .45″, Rectangular, Steel, Gage Block, ASME 0, Supplied with a Certificate of Inspection | Rectangular | 0.45″ | – | – |

| MIT-611217-531 | Gage Block | .75″, Rectangular, Steel, Gage Block, ASME 0, Supplied with a Certificate of Inspection | Rectangular | 0.75″ | – | – |

Inside Measuring Instruments

Inside measuring instruments are useful in measuring bores. Mitutoyo offers a mechanical and electronic instruments for bore measurement.* Both types offer two distinct measurement methods, two-point and three-point contact. Mechanical tools can further be divided by what type of scale used, direct reading or not.

Deciding between a two-point (Bore Gage) and three-point method (Holtest or Digimatic Holtest) is the first step in determining bore measurement devices. Bore gages and Holtests have their own advantages and disadvantages.

Bore gages can detect a more vivid geometric picture of the bore providing specific data on ovality, barrel, taper, and bell mouth. However, such information comes at the price of speed, as the inspection takes longer than the three-point method. With a MIN hold function, electronic bore gages can overcome excesses in inspection time.

Holtests are a quick and easy measurement tools. While they are fast and for anyone, they give an averaged reading of the overall picture. So, any outlying reading may lead to unwarranted additional inspections.

Both bore gages and holtests are with electronic and mechanical reading display devices. Electronic devices may have an output system to directly transfer data to another source.

*Air gaging is also offered in another category.

Gagemaker offers three types of Mitutoyo Inside Measuring Instruments.

- Bore Gages (Two-point method)

- Holtests (Three-point method)

- Digimatic Holtests (Three-point method)

| Image | Gagemaker Model | Description | Indicator Type | Range | Resolution | Accuracy | Quote |

|---|---|---|---|---|---|---|---|

| MIT-511-206 | .4-.74″ Dial Bore Gage w/2923SB-10 dial indicator, .0001″ graduation | Mechanical | .4 – .74″ | .0001″ | .0002″ | ||

| MIT-511-212 | .24-.4″ Dial Bore Gage w/2923SB-10 dial indicator, .0001″ graduation | Mechanical | .24 – .4″ | .0001″ | .0002″ | ||

| MIT-511-731 | .7-1.4″ Dial Bore Gage, indicator not included | Mechanical | .7 – 1.4″ | .0005″ | .0008″ | ||

| MIT-511-732 | 1.4-2.5″ Dial Bore Gage, indicator not included | Mechanical | 1.4 -2.5″ | .0005″ | .0008″ | ||

| MIT-511-733 | 2–6″ Dial Bore Gage, indicator not included | Mechanical | 2.0 – 6.0″ | .0005″ | .0008″ | ||

| MIT-511-741 | .7-1.4″ Dial Bore Gage w/2922SB dial indicator, .0005″ graduation | Mechanical | .700 – 1.400″ | .0005″ | .0008″ | ||

| MIT-511-742 | 1.4-2.5″ Dial Bore Gage w/2922SB dial indicator, .0005″ graduation | Mechanical | 1.4 -2.5″ | .0005″ | .0008″ | ||

| MIT-511-743 | 2–6″ Dial Bore Gage w/2922SB dial indicator, .0005″ graduation | Mechanical | 2 – 6″ | .0005″ | .0008″ | ||

| MIT-511-745 | 6.5-10″ Dial Bore Gage w/2922SB dial indicator, .0005″ graduation | Mechanical | 6.5 – 10″ | .0005″ | .0008″ | ||

| MIT-511-751 | .7-1.4″ Dial Bore Gage w/2923SB-10 dial indicator, .0001″ graduation | Mechanical | .7 – 1.4″ | .0001″ | .0008″ |

| Gagemaker Model | Product Type | Description | Indicator Type | Range | Resolution | Accuracy | Number of Points |

|---|---|---|---|---|---|---|---|

| MIT-368-263 | Holtest | .425-.5″, .0001″, Holtest, Titanium Nitride Coated Contact Points, Ratchet Stop | Mechanical | .425 – .5″ | .0002″ | ±.0001″ | 3 |

| MIT-368-264 | Holtest | .5-.65″, .0001″, Holtest, Titanium Nitride Coated Contact Points, Ratchet Stop | Mechanical | .5 – .65″ | .0002″ | ±.0001″ | 3 |

| MIT-368-265 | Holtest | .65-.8″, .0002″, Holtest, Titanium Nitride Coated Contact Points, Ratchet Stop | Mechanical | .65 – .8″ | .0002″ | ±.0001″ | 3 |

| MIT-368-266 | Holtest | .8-1″, .0002″, Holtest, Titanium Nitride Coated Contact Points, Ratchet Stop | Mechanical | .8 – 1″ | .0002″ | ±.00015″ | 3 |

| MIT-368-267 | Holtest | 1-1.2″, .0002″, Holtest, Titanium Nitride Coated Contact Points, Ratchet Stop | Mechanical | 1 – 1.2″ | .0002″ | ±.00015″ | 3 |

| MIT-368-268 | Holtest | 1.2-1.6″, .0002″, Holtest, Titanium Nitride Coated Contact Points, Ratchet Stop | Mechanical | 1.2 – 1.6″ | .0002″ | ±.00015″ | 3 |

| MIT-368-269 | Holtest | 1.6-2″, .0002″, Holtest, Titanium Nitride Coated Contact Points, Ratchet Stop | Mechanical | 1.6 – 2″ | .0002″ | ±.00015″ | 3 |

| MIT-368-270 | Holtest | 2-2.5″, .0002″, Holtest, Titanium Nitride Coated Contact Points, Ratchet Stop | Mechanical | 2 – 2.5″ | .0002″ | ±.00015″ | 3 |

| MIT-368-271 | Holtest | 2.5-3″, .0002″, Holtest, Titanium Nitride Coated Contact Points, Ratchet Stop | Mechanical | 2.5 – 3″ | .0002″ | ±.00015″ | 3 |

| MIT-368-272 | Holtest | 3-3.5″, .0002″, Holtest, Titanium Nitride Coated Contact Points, Ratchet Stop | Mechanical | 3 – 3.5″ | .0002″ | ±.00015″ | 3 |

| MIT-368-864 | Holtest | .5-.65″, .0002″, Holtest, Type II, Alloyed Steel Contact Points, Ratchet Stop | Mechanical | .5 – .65″ | .0002″ | ±.0001″ | 3 |

| MIT-368-865 | Holtest | .65-.8″, .0002″, Holtest, Type II, Alloyed Steel Contact Points, Ratchet Stop | Mechanical | .65 – .8″ | .0002″ | ±.0001″ | 3 |

| MIT-368-866 | Holtest | .8-1″, .0002″, Holtest, Type II, Alloyed Steel Contact Points, Ratchet Stop | Mechanical | .8 – 1″ | .0002″ | ±.00015″ | 3 |

| MIT-368-867 | Holtest | 1-1.2″, .0002″, Holtest, Type II, Alloyed Steel Contact Points, Ratchet Stop | Mechanical | 1 – 1.2″ | .0002″ | ±.00015″ | 3 |

| MIT-368-868 | Holtest | 1.2-1.6″, .0002″, Holtest, Type II, Alloyed Steel Contact Points, Ratchet Stop | Mechanical | 1.2 – 1.6″ | .0002″ | ±.00015″ | 3 |

| MIT-368-869 | Holtest | 1.6-2″, .0002″, Holtest, Type II, Alloyed Steel Contact Points, Ratchet Stop | Mechanical | 1.6 – 2″ | .0002″ | ±.00015″ | 3 |

| MIT-368-870 | Holtest | 2-2.5″, .0002″, Holtest, Type II, Alloyed Steel Contact Points, Ratchet Stop | Mechanical | 2 – 2.5″ | .0002″ | ±.00015″ | 3 |

| MIT-368-871 | Holtest | 2.5-3″, .0002″, Holtest, Type II, Alloyed Steel Contact Points, Ratchet Stop | Mechanical | 2.5 – 3″ | .0002″ | ±.00015″ | 3 |

| MIT-368-872 | Holtest | 3-3.5″, .0002″, Holtest, Type II, Alloyed Steel Contact Points, Ratchet Stop | Mechanical | 3 – 3.5″ | .0002″ | ±.00015″ | 3 |

| MIT-368-873 | Holtest | 3.5-4″, .0002″, Holtest, Type II, Alloyed Steel Contact Points, Ratchet Stop | Mechanical | 3.5 – 4″ | .0002″ | ±.00015″ | 3 |

| MIT-368-874 | Holtest | 4-5″, .0002″, Holtest, Type II, Alloyed Steel Contact Points, Ratchet Stop | Mechanical | 4 – 5″ | .0002″ | ±.00025″ | 3 |

| MIT-368-875 | Holtest | 5-6″, .0002″, Holtest, Type II, Alloyed Steel Contact Points, Ratchet Stop | Mechanical | 5 – 6″ | .0002″ | ±.00025″ | 3 |

| MIT-368-876 | Holtest | 6-7″, .0002″, Holtest, Type II, Alloyed Steel Contact Points, Ratchet Stop | Mechanical | 6 – 7″ | .0002″ | ±.00025″ | 3 |

| MIT-368-877 | Holtest | 7-8″, .0002″, Holtest, Type II, Alloyed Steel Contact Points, Ratchet Stop | Mechanical | 7 – 8″ | .0002″ | ±.00025″ | 3 |

| MIT-04AZA721 | Holtest Head | .5-.65″, Holtest(368-264), Digimatic Holtest(468-264), Borematic(568-464) Replacement Head Assembly, Titanium Nitride Coated Contact Points | – | – | – | – | – |

| MIT-04AZA722 | Holtest Head | .65-.8″, Holtest(368-265), Digimatic Holtest(468-265), Borematic(568-465) Replacement Head Assembly, Titanium Nitride Coated Contact Points | – | – | – | – | – |

| MIT-04AZA730 | Holtest Head | .8-.1″, Holtest(368-266), Digimatic Holtest(468-266), Borematic(568-466) Replacement Head Assembly, Titanium Nitride Coated Contact Points | – | – | – | – | – |

| MIT-04AZA731 | Holtest Head | 1-1.2″, Holtest(368-267), Digimatic Holtest(468-267), Borematic(568-467) Replacement Head Assembly, Titanium Nitride Coated Contact Points | – | – | – | – | – |

| MIT-04AZA739 | Holtest Head | 1.2-1.6″, Holtest(368-268), Digimatic Holtest(468-268), Borematic(568-468) Replacement Head Assembly, Titanium Nitride Coated Contact Points | – | – | – | – | – |

| MIT-04AZA740 | Holtest Head | 1.6-2″, Holtest(368-269), Digimatic Holtest(468-269), Borematic(568-469) Replacement Head Assembly, Titanium Nitride Coated Contact Points | – | – | – | – | – |

| Gagemaker Model | Description | Indicator Type | Range | Resolution | Accuracy | SPC Output |

|---|---|---|---|---|---|---|

| MIT-468-263 | .425-.5″/10.795-12.7mm, .00005″/0.001mm, Digimatic Holtest, Titanium Nitride Coated Contact Points, With SPC Output, Ratchet Stop | Digimatic | .425 – .5″/ 10.795 – 12.7mm | .00005″/0.001mm | ±.0001″ | Yes |

| MIT-468-264 | .5-.65″/12.7-16.51mm, .00005″/0.001mm, Digimatic Holtest, Titanium Nitride Coated Contact Points, With SPC Output, Ratchet Stop | Digimatic | .5 – .65″/ 12.7 – 16.51mm | .00005″/0.001mm | ±.0001″ | Yes |

| MIT-468-265 | .65-.8″/16.51-20.32mm, .00005″/0.001mm, Digimatic Holtest, Titanium Nitride Coated Contact Points, With SPC Output, Ratchet Stop | Digimatic | .65 – .8″/ 16.51 – 20.32mm | .00005″/0.001mm | ±.0001″ | Yes |

| MIT-468-266 | .8-1″/20.32-25.4mm, .00005″/0.001mm, Digimatic Holtest, Titanium Nitride Coated Contact Points, With SPC Output, Ratchet Stop | Digimatic | .8 – 1″/ 20.32 – 25.4mm | .00005″/0.001mm | ±.00015″ | Yes |

| MIT-468-267 | 1-1.2″/25.4-30.48mm, .00005″/0.001mm, Digimatic Holtest, Titanium Nitride Coated Contact Points, With SPC Output, Ratchet Stop | Digimatic | 1 – 1.2″/ 25.4 – 30.48mm | .00005″/0.001mm | ±.00015″ | Yes |

| MIT-468-268 | 1.2-1.6″/30.48-40.64mm, .00005″/0.001mm, Digimatic Holtest, Titanium Nitride Coated Contact Points, With SPC Output, Ratchet Stop | Digimatic | 1.2 – 1.6″/ 30.48 – 40.64mm | .00005″/0.001mm | ±.00015″ | Yes |

| MIT-468-269 | 1.6-2″/40.64-50.8mm, .00005″/0.001mm, Digimatic Holtest, Titanium Nitride Coated Contact Points, With SPC Output, Ratchet Stop | Digimatic | 1.6 – 2″/ 40.64 – 50.8mm | .00005″/0.001mm | ±.00015″ | Yes |

| MIT-468-270 | 2-2.5″/50.8-63.5mm, .00005″/0.001mm, Digimatic Holtest, Titanium Nitride Coated Contact Points, With SPC Output, Ratchet Stop | Digimatic | 2 – 2.5″/ 50.8 – 63.5mm | .00005″/0.001mm | ±.00015″ | Yes |

| MIT-468-271 | 2.5-3″/63.5-76.2mm, .00005″/0.001mm, Digimatic Holtest, Titanium Nitride Coated Contact Points, With SPC Output, Ratchet Stop | Digimatic | 2.5 – 3″/ 63.5 – 76.2mm | .00005″/0.001mm | ±.00015″ | Yes |

| MIT-468-272 | 3-3.5″/76.2-88.9mm, .00005″/0.001mm, Digimatic Holtest, Titanium Nitride Coated Contact Points, With SPC Output, Ratchet Stop | Digimatic | 3 – 3.5″/ 76.2 – 88.9mm | .00005″/0.001mm | ±.00015″ | Yes |

| MIT-468-273 | 3.5-4″/88.9-101.6mm, .00005″/0.001mm, Digimatic Holtest, Titanium Nitride Coated Contact Points, With SPC Output, Ratchet Stop | Digimatic | 3.5 – 4″/ 88.9 – 101.6mm | .00005″/0.001mm | ±.00015″ | Yes |

| MIT-468-274 | 4-5″/101.6-127mm, .00005″/0.001mm, Digimatic Holtest, Titanium Nitride Coated Contact Points, With SPC Output, Ratchet Stop | Digimatic | 4 – 5″/ 101.6 – 127mm | .0001″/0.001mm | ±.00025″ | Yes |

| MIT-468-275 | 5-6″/127-152.4mm, .0001″/0.001mm, Digimatic Holtest, With SPC Output, Ratchet Stop | Digimatic | 5 – 6″/ 127 – 152.4mm | .0001″/0.001mm | ±.00025″ | Yes |

| MIT-468-276 | 6-7″/152.4-177.8mm, .0001″/0.001mm, Digimatic Holtest, With SPC Output, Ratchet Stop | Digimatic | 6 – 7″/ 152.4 – 177.8mm | .0001″/0.001mm | ±.00025″ | Yes |

| MIT-468-277 | 7-8″/177.8-203.2mm, .0001″/0.001mm, Digimatic Holtest, With SPC Output, Ratchet Stop | Digimatic | 7 – 8″/ 177.8 – 203.2mm | .0001″/0.001mm | ±.00025″ | Yes |

| MIT-468-278 | 8-9″/203.2-228.6mm, .0001″/0.001mm, Digimatic Holtest, With SPC Output, Ratchet Stop | Digimatic | 8 – 9″/ 203.2 – 228.6mm | .0001″/0.001mm | ±.00025″ | Yes |

| MIT-468-279 | 9-10″/228.6-254mm, .0001″/0.001mm, Digimatic Holtest, With SPC Output, Ratchet Stop | Digimatic | 9 – 10″/ 228.6 – 254mm | .0001″/0.001mm | ±.00025″ | Yes |

| MIT-468-280 | 10-11″/254-279.4mm, .0001″/0.001mm, Digimatic Holtest, With SPC Output, Ratchet Stop | Digimatic | 10 – 11″/ 254 – 279.4mm | .0001″/0.001mm | ±.00025″ | Yes |

| MIT-468-281 | 11-12″/279.4-304.8mm, .0001″/0.001mm, Digimatic Holtest, With SPC Output, Ratchet Stop | Digimatic | 11 – 12″/ 279.4 – 304.8mm | .0001″/0.001mm | ±.00025″ | Yes |

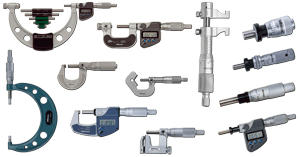

Micrometers

Micrometers are industry standard measuring tools because of their high accuracy and resolution and ease of use. Mechanical micrometers are available in .001” and .0001” (0.01mm and 0.001mm) graduations. Digimatic micrometers (electronic displays) normally have .0001” or .00005” and 0.001mm resolutions. Standard micrometers are available up to 40”/1,000mm, but larger micrometers can be manufactured as a special-order item.

Many types of specialty micrometers are available to measure difficult-to-reach features. While many types of slip-on anvil adapters are available, a specialty micrometer is the best tool for the job.

Gagemaker offers these styles of Mitutoyo micrometers and parts:

- Digimatic Micrometers

- Mechanical Micrometers

- Micrometer Heads

- Micrometer Standards

| Gagemaker Model | Product Type | Description | Indicator Type | Range | Resolution | Accuracy | SPC Output | Spindle Face |

|---|---|---|---|---|---|---|---|---|

| MIT-422-330 | Blade Micrometer | 0-1″/0-25.4mm, .00005″/0.001mm Digimatic Blade Micrometer, .75mm Blade Thickness, Non-Rotating Spindle, With SPC Data Output, Ratchet Stop | Digimatic | 0 – 1″/0 – 25.4mm | .00005″/0.001mm | ±.00015″ | Yes | Flat |

| MIT-422-331 | Blade Micrometer | 1-2″/25.4-50.8mm, .00005″/0.001mm Digimatic Blade Micrometer, .75mm Blade Thickness, Non-Rotating Spindle, With SPC Data Output, Ratchet Stop | Digimatic | 1 – 2″/25.4 – 50.8mm | .00005″/0.001mm | ±.00015″ | Yes | Flat |

| MIT-422-332 | Blade Micrometer | 2-3″/50.8-76.2mm, .00005″/0.001mm Digimatic Blade Micrometer, .75mm Blade Thickness, Non-Rotating Spindle, With SPC Data Output, Ratchet Stop | Digimatic | 2 – 3″/50.8 – 76.2mm | .00005″/0.001mm | ±.00015″ | Yes | Flat |

| MIT-422-333 | Blade Micrometer | 3-4″/76.2-101.6mm, .00005″/0.001mm Digimatic Blade Micrometer, .75mm Blade Thickness, Non-Rotating Spindle, With SPC Data Output, Ratchet Stop | Digimatic | 3 – 4″/76.2 – 101.6mm | .00005″/0.001mm | ±.00015″ | Yes | Flat |

| MIT-422-360 | Blade Micrometer | 0-1″/0-25.4mm, .00005″/0.001mm Digimatic Blade Micrometer, .4mm Blade Thickness, Non-Rotating Spindle, With SPC Data Output, Ratchet Stop | Digimatic | 0 – 1″/0 – 25.4mm | .00005″/0.001mm | ±.00015″ | Yes | Flat |

| MIT-422-370 | Blade Micrometer | 0-1″/0-25.4mm, .00005″/0.001mm Digimatic Blade Micrometer, .75mm Carbide Tipped Blade Thickness, Non-Rotating Spindle, With SPC Data Output, Ratchet Stop | Digimatic | 0 – 1″/0 – 25.4mm | .00005″/0.001mm | ±.00015″ | Yes | Flat |

| MIT-422-371 | Blade Micrometer | 0-1″/0-25.4mm, .00005″/0.001mm Digimatic Blade Micrometer, .4mm Carbide Tipped Blade Thickness, Non-Rotating Spindle, With SPC Data Output, Ratchet Stop | Digimatic | 0 – 1″/0 – 25.4mm | .00005″/0.001mm | ±.00015″ | Yes | Flat |

| MIT-345-350-10 | Caliper Type Micrometer | .2-1.2″/5-30mm, .00005″/0.001mm Digimatic Caliper Jaw Type Micrometer, Carbide Steel Tip, Locking Clamp, With SPC Data Output, Ratchet Stop | Digimatic | .2 – 1.2″/5-30mm | .00005″/0.001mm | ±.00025″ | Yes | – |

| MIT-345-351-10 | Caliper Type Micrometer | 1-2″/25-50mm, .00005″/0.001mm Digimatic Caliper Jaw Type Micrometer, Carbide Steel Tip, Locking Clamp, With SPC Data Output, Ratchet Stop | Digimatic | 1 – 2″/25-50mm | .00005″/0.001mm | ±.0003″ | Yes | – |

| MIT-342-371 | Crimp Height Micrometer | 0-.8″/0-20mm, .00005″/0.001mm Digimatic Crimp Height Micrometer, 60 Degree Point, With SPC Data Output, Ratchet Stop | Digimatic | 0 – .8″/0 – 20mm | .00005″/0.001mm | ±.00015″ | Yes | Point |

| MIT-389-351 | Deep Throat Micrometer | 0-1″/0-25.4mm, .00005″/0.001mm IP65 Digimatic Sheet Metal Micrometer, With SPC Data Output, Ratchet Stop | Digimatic | 0 – 1″/0 – 25.4mm | .00005″/0.001mm | ±.0002″ | Yes | Flat |

| MIT-389-352 | Deep Throat Micrometer | 1-2″/25.4-50.8mm, .00005″/0.001mm IP65 Digimatic Sheet Metal Micrometer, With SPC Data Output, Ratchet Stop, With Standard | Digimatic | 1 – 2″/25.4 – 50.8mm | .00005″/0.001mm | ±.0002″ | Yes | Flat |

| MIT-329-350-10 | Depth Micrometer | 0-6″/0-152.4, .00005″/0.001mm Digimatic Depth Micrometer, 6 interchangeable rods (1″/25.4mm increments), Rod Clamp, 4″ Base, With SPC Data Output, Ratchet Stop | Digimatic | 0 – 6″/0 – 152.4mm | .00005″/0.001mm | ±.00012″/±3µm | Yes | – |

| MIT-329-351-10 | Depth Micrometer | 0-12″/0-304.8, .00005″/0.001mm Digimatic Depth Micrometer, 12 interchangeable rods (1″/25.4mm increments), Rod Clamp, 4″ Base, With SPC Data Output, Ratchet Stop | Digimatic | 0 – 12″/0 – 304.8mm | .00005″/0.001mm | ±.00012″/±3µm | Yes | – |

| MIT-164-164 | Digimatic Micrometer Head | 2″/50.8mm, .0005″/0.01mm, Digimatic Micrometer Head, With SPC Data Output, 330 Degree Rotating Face | Digital | 0 – 2″/0 – 50.8mm | .00005″/0.001mm | ±.00015″ | Yes | – |

| MIT-323-350 | Disk Micrometer | 0-1″/0-25.4mm, .00005″/0.001mm IP65 Digimatic Disk Micrometer, .787″/20mm Diameter .028″/0.7mm Edge Thickness Disk, With SPC Data Output, Ratchet Stop | Digimatic | 0 – 1″/0 – 25.4mm | .00005″/0.001mm | ±.0002″ | Yes | Disk |

| MIT-323-351 | Disk Micrometer | 1-2″/25.4-50.8mm, .00005″/0.001mm IP65 Digimatic Disk Micrometer, .787″/20mm Diameter .028″/0.7mm Edge Thickness Disk, With SPC Data Output, Ratchet Stop, With Standard | Digimatic | 1 – 2″/25.4 – 50.8mm | .00005″/0.001mm | ±.0002″ | Yes | Disk |

| MIT-323-352 | Disk Micrometer | 2-3″/50.8-76.2mm, .00005″/0.001mm IP65 Digimatic Disk Micrometer, .787″/20mm Diameter .028″/0.7mm Edge Thickness Disk, With SPC Data Output, Ratchet Stop, With Standard | Digimatic | 2 – 3″/50 – 76.2mm | .00005″/0.001mm | ±.0003″ | Yes | Disk |

| MIT-369-350 | Disk Micrometer | 0-1″/0-25.4mm, .00005″/0.001mm Digimatic Disk Micrometer, .787″/20mm Diameter .028″/0.7mm Edge Thickness Disk, Non-Rotating Spindle, With SPC Data Output, Ratchet Stop | Digimatic | 0 – 1″/0 – 25.4mm | .00005″/0.001mm | ±.0002″ | Yes | Disk |

| MIT-293-100 | MDH Micrometer | 0-25mm, 0.0001mm/0.0005mm switchable MDH Digimatic Outside Micrometer, With Output | Digimatic | 0 – 25mm | 0.0001mm | ±0.5μm | Yes | Flat |

| MIT-293-130 | MDH Micrometer | 0-1″/0-25.4mm, .00005″/.00002″/0.0001mm/0.0005mm switchable, MDH Digimatic Outside Micrometer, With Output | Digimatic | 0 – 1″/0 – 25.4mm | .000005 In | ±.00002″ | Yes | Flat |

| MIT-293-230-30 | Micrometer | 0-25mm, 0.001mm, IP65 Digimatic Outside Micrometer, With SPC Data Output, Ratchet Stop | Digimatic | 0 – 25mm | 0.001mm | ±1µm | Yes | Flat |

| MIT-293-231-30 | Micrometer | 25-50mm, .001mm, IP65 Digimatic Outside Micrometer, With SPC Data Output, Ratchet Stop, With Standard | Digimatic | 25 – 50mm | 0.001mm | ±1µm | Yes | Flat |

| MIT-293-232-30 | Micrometer | 50-75mm, .001mm, IP65 Digimatic Outside Micrometer, With SPC Data Output, Ratchet Stop, With Standard | Digimatic | 50 – 75mm | 0.001mm | ±2µm | Yes | Flat |

| MIT-293-233-30 | Micrometer | 75-100mm, .001mm, IP65 Digimatic Outside Micrometer, With SPC Data Output, Ratchet Stop, With Standard | Digimatic | 75 – 100mm | 0.001mm | ±2µm | Yes | Flat |

| MIT-293-240-30 | Micrometer | 0-25mm, 0.001mm, IP65 Digimatic Outside Micrometer, No Output, Ratchet Stop | Digimatic | 0 – 25mm | 0.001mm | ±1µm | No | Flat |

| MIT-293-241-30 | Micrometer | 25-50mm, .001mm, IP65 Digimatic Outside Micrometer, No Output, Ratchet Stop, With Standard | Digimatic | 25 – 50mm | 0.001mm | ±1µm | No | Flat |

| MIT-293-330-30 | Micrometer | 0-1″/0-25.4mm, .00005″/0.001mm IP65 Digimatic Outside Micrometer, With SPC Data Output, Ratchet Stop | Digimatic | 0 – 1″/0 – 25.4mm | .00005″/0.001mm | ±.00005″ | Yes | Flat |

| MIT-293-331-30 | Micrometer | 1-2″/25.4-50.8mm, .00005″/0.001mm IP65 Digimatic Outside Micrometer, With SPC Data Output, Ratchet Stop, With Standard | Digimatic | 1 – 2″/25.4 – 50.8mm | .00005″/0.001mm | ±.00005″ | Yes | Flat |

| MIT-293-332-30 | Micrometer | 2-3″/50.8-76.2mm, .00005″/0.001mm IP65 Digimatic Outside Micrometer, With SPC Data Output, Ratchet Stop, With Standard | Digimatic | 2 – 3″/50.8 – 76.2mm | .00005″/0.001mm | ±.00005″ | Yes | Flat |

| Gagemaker Model | Product Type | Third Drill Down | Description | Pieces Per Set | Range | Resolution | Accuracy | Contact Point Diameter | Contact Point Flatness | Base Flatness | Parallelism |

|---|---|---|---|---|---|---|---|---|---|---|---|

| MIT-201217 | Rod Anvil | Anvil | .118 In/3mm Diameter Rod Anvil for Uni-Mike | – | – | – | – | .118″ | – | – | – |

| MIT-208100 | Spindle Attachment Tip | Blade Spindle | .75mm Thickness, Blade Spindle Attachment Tip for Inch Micrometers | – | – | – | – | – | – | – | – |

| MIT-101-113 | Micrometer | Outside Micrometers | 0-1 In, .0001 In Mechanical Outside Micrometer, Satin Chrome, Ratchet Stop | – | 0 – 1″ | .0001″ | ±.0001″ | .25″ | .000024″ | – | .00008 In |

| MIT-101-114 | Micrometer | Outside Micrometers | 1-2 In, .0001 In Mechanical Outside Micrometer, Satin Chrome, Ratchet Stop, With Standard | – | 1 – 2″ | .0001″ | ±.0001″ | .25″ | .000024″ | – | .00008 In |

| MIT-101-117 | Micrometer | Outside Micrometers | 0-1 In, .0001 In Mechanical Outside Micrometer, Satin Chrome, Friction Thimble | – | 0 – 1″ | .0001″ | ±.0001″ | .25″ | .000024″ | – | .00008 In |

| MIT-101-118 | Micrometer | Outside Micrometers | 1-2 In, .0001 In Mechanical Outside Micrometer, Satin Chrome, Friction Thimble, With Standard | – | 1 – 2″ | .0001″ | ±.0001″ | .25″ | .000024″ | – | .00008 In |

| MIT-101-119 | Micrometer | Outside Micrometers | 2-3 In, .0001 In Mechanical Outside Micrometer, Satin Chrome, Ratchet Stop, With Standard | – | 2 – 3″ | .0001″ | ±.0001″ | .25″ | .000024″ | – | .00008 In |

| MIT-101-120 | Micrometer | Outside Micrometers | 3-4 In, .0001 In Mechanical Outside Micrometer, Satin Chrome, Ratchet Stop, With Standard | – | 3 – 4″ | .0001″ | ±.00015″ | .25″ | .000024″ | – | .00008 In |

| MIT-101-717 | Micrometer | Outside Micrometers | 0-1 In, .0001 In Mechanical Outside Micrometer, Satin Chrome, Smooth Action, Ratchet Thimble | – | 0 – 1″ | .0001″ | ±.0001″ | 6.35mm | .000024″ | – | .00008 In |

| MIT-102-717 | Micrometer | Outside Micrometers | 0-1 In, .0001 In Mechanical Outside Micrometer, Smooth Action, Ratchet Thimble | – | 0 – 1″ | .0001″ | ±.0001″ | 6.35mm | .000024″ | – | .00008 In |

| MIT-102-718 | Micrometer | Outside Micrometers | 1-2 In, .0001 In Mechanical Outside Micrometer, Smooth Action, Ratchet Thimble, With Standard | – | 1 – 2″ | .0001″ | ±.0001″ | 6.35mm | .000024″ | – | .00008 In |

| MIT-103-131 | Micrometer | Outside Micrometers | 0-1 In, .0001 In Mechanical Outside Micrometer, Hammertone Baked Enamel, Ratchet Stop | – | 0 – 1″ | .0001″ | ±.0001″ | 6.35mm | .000024″ | – | [.00008+.00004(L/4)]In |

| MIT-103-132 | Micrometer | Outside Micrometers | 1-2 In, .0001 In Mechanical Outside Micrometer, Hammertone Baked Enamel, Ratchet Stop, With Standard | – | 1 – 2″ | .0001″ | ±.0001″ | 6.35mm | .000024″ | – | [.00008+.00004(L/4)]In |

| MIT-103-135 | Micrometer | Outside Micrometers | 0-1 In, .0001 In Mechanical Outside Micrometer, Hammertone Baked Enamel, Friction Thimble | – | 0 – 1″ | .0001″ | ±.0001″ | 6.35mm | .000024″ | – | [.00008+.00004(L/4)]In |

| MIT-103-136 | Micrometer | Outside Micrometers | 1-2 In, .0001 In Mechanical Outside Micrometer, Hammertone Baked Enamel, Friction Thimble, With Standard | – | 1 – 2″ | .0001″ | ±.0001″ | 6.35mm | .000024″ | – | [.00008+.00004(L/4)]In |

| MIT-103-137 | Micrometer | Outside Micrometers | 0-25mm, 0.01mm Mechanical Outside Micrometer, Hammertone Baked Enamel, Ratchet Stop | – | 0 – 25mm | 0.01mm | ±2µm | 6.35mm | 0.6µm | – | (2+R/100)µm |

| MIT-103-138 | Micrometer | Outside Micrometers | 25-50mm, 0.01mm Mechanical Outside Micrometer, Hammertone Baked Enamel, Ratchet Stop, With Standard | – | 25 – 50mm | 0.01mm | ±2µm | 6.35mm | 0.6µm | – | (2+R/100)µm |

| MIT-103-139-10 | Micrometer | Outside Micrometers | 50-75mm, 0.01mm Mechanical Outside Micrometer, Hammertone Baked Enamel, Ratchet Stop, With Standard | – | 50 – 75mm | 0.01mm | ±2µm | 6.35mm | 0.6µm | – | (2+R/100)µm |

| MIT-103-140-10 | Micrometer | Outside Micrometers | 75-100mm, 0.01mm Mechanical Outside Micrometer, Hammertone Baked Enamel, Ratchet Stop, With Standard | – | 75 – 100mm | 0.01mm | ±2µm | 6.35mm | 0.6µm | – | (2+R/100)µm |

| MIT-103-141-10 | Micrometer | Outside Micrometers | .10-.50″ Dial Caliper Gage, .0002″, ± .0008″ | – | 100 – 125mm | 0.01mm | ±2µm | 6.35mm | 0.6µm | – | (2+R/100)µm |

| MIT-103-142-10 | Micrometer | Outside Micrometers | 125-150mm, 0.01mm Mechanical Outside Micrometer, Hammertone Baked Enamel, Ratchet Stop, With Standard | – | 125 – 150mm | 0.01mm | ±2µm | 6.35mm | 0.6µm | – | (2+R/100)µm |

| MIT-103-143-10 | Micrometer | Outside Micrometers | 150-175mm, 0.01mm Mechanical Outside Micrometer, Hammertone Baked Enamel, Ratchet Stop, With Standard | – | 150 – 175mm | 0.01mm | ±2µm | 6.35mm | 0.6µm | – | (2+R/100)µm |

| MIT-103-177 | Micrometer | Outside Micrometers | 0-1 In, .001 In Mechanical Outside Micrometer, Hammertone Baked Enamel, Ratchet Stop | – | 0 – 1″ | .001″ | ±.0001″ | 6.35mm | .000024″ | – | [.00008+.00004(L/4)]In |

| MIT-103-178 | Micrometer | Outside Micrometers | 1-2 In, .001 In Mechanical Outside Micrometer, Hammertone Baked Enamel, Ratchet Stop, With Standard | – | 1 – 2″ | .001″ | ±.0001″ | 6.35mm | .000024″ | – | [.00008+.00004(L/4)]In |

| MIT-103-179 | Micrometer | Outside Micrometers | 2-3 In, .001 In Mechanical Outside Micrometer, Hammertone Baked Enamel, Ratchet Stop, With Standard | – | 2 – 3″ | .001″ | ±.0001″ | 6.35mm | .000024″ | – | [.00008+.00004(L/4)]In |

| MIT-103-180 | Micrometer | Outside Micrometers | 3-4 In, .001 In Mechanical Outside Micrometer, Hammertone Baked Enamel, Ratchet Stop, With Standard | – | 3 – 4″ | .001″ | ±.00015″ | 6.35mm | .000024″ | – | [.00008+.00004(L/4)]In |

| MIT-103-181 | Micrometer | Outside Micrometers | 4-5 In, .001 In Mechanical Outside Micrometer, Hammertone Baked Enamel, Ratchet Stop, With Standard | – | 4 – 5″ | .001″ | ±.00015″ | 6.35mm | .000024″ | – | [.00008+.00004(L/4)]In |

| MIT-103-182 | Micrometer | Outside Micrometers | 5-6 In, .001 In Mechanical Outside Micrometer, Hammertone Baked Enamel, Ratchet Stop, With Standard | – | 5 – 6″ | .001″ | ±.00015″ | 6.35mm | .000024″ | – | [.00008+.00004(L/4)]In |

| MIT-103-183 | Micrometer | Outside Micrometers | 6-7 In, .001 In Mechanical Outside Micrometer, Hammertone Baked Enamel, Ratchet Stop, With Standard | – | 6 – 7″ | .001″ | ±.0002″ | 6.35mm | .000024″ | – | [.00008+.00004(L/4)]In |

| MIT-103-184 | Micrometer | Outside Micrometers | 7-8 In, .001 In Mechanical Outside Micrometer, Hammertone Baked Enamel, Ratchet Stop, With Standard | – | 7 – 8″ | .001″ | ±.0002″ | 6.35mm | .000024″ | – | [.00008+.00004(L/4)]In |

| MIT-103-185 | Micrometer | Outside Micrometers | 8-9 In, .001 In Mechanical Outside Micrometer, Hammertone Baked Enamel, Ratchet Stop, With Standard | – | 8 – 9″ | .001″ | ±.0002″ | 6.35mm | .000024″ | – | [.00008+.00004(L/4)]In |

| MIT-103-186 | Micrometer | Outside Micrometers | 9-10 In, .001 In Mechanical Outside Micrometer, Hammertone Baked Enamel, Ratchet Stop, With Standard | – | 9 – 10″ | .001″ | ±.00025″ | 6.35mm | .000024″ | – | [.00008+.00004(L/4)]In |

| MIT-103-187 | Micrometer | Outside Micrometers | 10-11 In, .001 In Mechanical Outside Micrometer, Hammertone Baked Enamel, Ratchet Stop, With Standard | – | 10 – 11″ | .001″ | ±.00025″ | 6.35mm | .000024″ | – | [.00008+.00004(L/4)]In |

| MIT-103-188 | Micrometer | Outside Micrometers | 11-12 In, .001 In Mechanical Outside Micrometer, Hammertone Baked Enamel, Ratchet Stop, With Standard | – | 11 – 12″ | .001″ | ±.00025″ | 6.35mm | .000024″ | – | [.00008+.00004(L/4)]In |

| MIT-103-189 | Micrometer | Outside Micrometers | 12-13 In, .001 In Mechanical Outside Micrometer, Hammertone Baked Enamel, Ratchet Stop, With Standard | – | 12 – 13″ | .001″ | ±.0003″ | 6.35mm | .000024″ | – | [.00008+.00004(L/4)]In |

| MIT-103-190 | Micrometer | Outside Micrometers | 13-14 In, .001 In Mechanical Outside Micrometer, Hammertone Baked Enamel, Ratchet Stop, With Standard | – | 13 – 14″ | .001″ | ±.0003″ | 6.35mm | .000024″ | – | [.00008+.00004(L/4)]In |

| MIT-103-191 | Micrometer | Outside Micrometers | 14-15 In, .001 In Mechanical Outside Micrometer, Hammertone Baked Enamel, Ratchet Stop, With Standard | – | 14 – 15″ | .001″ | ±.0003″ | 6.35mm | .000024″ | – | [.00008+.00004(L/4)]In |

| MIT-103-192 | Micrometer | Outside Micrometers | 15-16 In, .001 In Mechanical Outside Micrometer, Hammertone Baked Enamel, Ratchet Stop, With Standard | – | 15 – 16″ | .001″ | ±.00035″ | 6.35mm | .000024″ | – | [.00008+.00004(L/4)]In |

| MIT-103-193 | Micrometer | Outside Micrometers | 16-17 In, .001 In Mechanical Outside Micrometer, Hammertone Baked Enamel, Ratchet Stop, With Standard | – | 16 – 17″ | .001″ | ±.00035″ | 6.35mm | .000024″ | – | [.00008+.00004(L/4)]In |

| MIT-103-194 | Micrometer | Outside Micrometers | 17-18 In, .001 In Mechanical Outside Micrometer, Hammertone Baked Enamel, Ratchet Stop, With Standard | – | 17 – 18″ | .001″ | ±.00035″ | 6.35mm | .000024″ | – | [.00008+.00004(L/4)]In |

| MIT-103-217 | Micrometer | Outside Micrometers | 2-3 In, .0001 In Mechanical Outside Micrometer, Hammertone Baked Enamel, Ratchet Stop, With Standard | – | 2 – 3″ | .0001″ | ±.0001″ | 6.35mm | .000024″ | – | [.00008+.00004(L/4)]In |

| MIT-103-218 | Micrometer | Outside Micrometers | 3-4 In, .0001 In Mechanical Outside Micrometer, Hammertone Baked Enamel, Ratchet Stop, With Standard | – | 3 – 4″ | .0001″ | ±.00015″ | 6.35mm | .000024″ | – | [.00008+.00004(L/4)]In |

| MIT-103-219 | Micrometer | Outside Micrometers | 4-5 In, .0001 In Mechanical Outside Micrometer, Hammertone Baked Enamel, Ratchet Stop, With Standard | – | 4 – 5″ | .0001″ | ±.00015″ | 6.35mm | .000024″ | – | [.00008+.00004(L/4)]In |

| MIT-103-220 | Micrometer | Outside Micrometers | 5-6 In, .0001 In Mechanical Outside Micrometer, Hammertone Baked Enamel, Ratchet Stop, With Standard | – | 5 – 6″ | .0001″ | ±.00015″ | 6.35mm | .000024″ | – | [.00008+.00004(L/4)]In |

| MIT-103-221 | Micrometer | Outside Micrometers | 6-7 In, .0001 In Mechanical Outside Micrometer, Hammertone Baked Enamel, Ratchet Stop, With Standard | – | 6 – 7″ | .0001″ | ±.0002″ | 6.35mm | .000024″ | – | [.00008+.00004(L/4)]In |

| MIT-103-222 | Micrometer | Outside Micrometers | 7-8 In, .0001 In Mechanical Outside Micrometer, Hammertone Baked Enamel, Ratchet Stop, With Standard | – | 7 – 8″ | .0001″ | ±.0002″ | 6.35mm | .000024″ | – | [.00008+.00004(L/4)]In |

| MIT-103-223 | Micrometer | Outside Micrometers | 8-9 In, .0001 In Mechanical Outside Micrometer, Hammertone Baked Enamel, Ratchet Stop, With Standard | – | 8 – 9″ | .0001″ | ±.0002″ | 6.35mm | .000024″ | – | [.00008+.00004(L/4)]In |

| MIT-103-224 | Micrometer | Outside Micrometers | 9-10 In, .0001 In Mechanical Outside Micrometer, Hammertone Baked Enamel, Ratchet Stop, With Standard | – | 9 – 10″ | .0001″ | ±.00025″ | 6.35mm | .000024″ | – | [.00008+.00004(L/4)]In |

| MIT-103-225 | Micrometer | Outside Micrometers | 10-11 In, .0001 In Mechanical Outside Micrometer, Hammertone Baked Enamel, Ratchet Stop, With Standard | – | 10 – 11″ | .0001″ | ±.00025″ | 6.35mm | .000024″ | – | [.00008+.00004(L/4)]In |

| MIT-103-226 | Micrometer | Outside Micrometers | 11-12 In, .0001 In Mechanical Outside Micrometer, Hammertone Baked Enamel, Ratchet Stop, With Standard | – | 11 – 12″ | .0001″ | ±.00025″ | 6.35mm | .000024″ | – | [.00008+.00004(L/4)]In |

| Gagemaker Model | Head Type | Description | Range | Resolution | Accuracy | Contact Point Diameter | Stem Diameter | Thimble Dia. | Spindle Face |

|---|---|---|---|---|---|---|---|---|---|

| MIT-148-111 | Common | 0-.5″ .001″ Mechanical Micrometer Head, .375″ Diameter Stem with Clamp Nut, Flat Spindle Face | 0 – .5″ | .001″ | ±.0001″ | 5mm | .375″ | 13mm | Flat |

| MIT-148-112 | Common | 0-.5″ .001″ Mechanical Micrometer Head, .375″ Diameter Plain Stem, Flat Spindle Face | 0 – .5″ | .001″ | ±.0001″ | 5mm | .375″ | 13mm | Flat |

| MIT-148-121 | Common | 0-13mm, 0.01mm, Mechanical Micrometer Head, 9.5mm Diameter Plain Stem, Flat Spindle Face, Spindle Lock | 0 – 13mm | .01mm | ±2µm | 5mm | 9.5mm | 13mm | Flat |

| MIT-148-122 | Common | 0-.5″ .001″ Mechanical Micrometer Head, .375″ Diameter Stem with Clamp Nut, Flat Spindle Face, Spindle Lock | 0 – .5″ | .001″ | ±.0001″ | 5mm | .375″ | 13mm | Flat |

| MIT-148-201 | Ultra-Small/Small | 0-6.5mm, 0.01mm, Mechanical Micrometer Head, Ultra-Small, 6mm Diameter Plain Stem, Flat Spindle Face | 0 – 6.5mm | .01mm | ±5µm | 3.5mm | 6mm | 9.3mm | Flat |

| MIT-148-202 | Ultra-Small/Small | 0-.25″ .001″ Mechanical Micrometer Head, .25″ Diameter Plain Stem, Flat Spindle Face | 0 -.25″ | .001″ | ±5µm | 3.5mm | .25″ | 9.3mm | Flat |

| MIT-148-203 | Ultra-Small/Small | 0-6.5mm, 0.01mm, Mechanical Micrometer Head, Ultra-Small, 6mm Diameter Stem with Clamp Nut, Flat Spindle Face | 0 – 6.5mm | .01mm | ±5µm | 3.5mm | 6mm | 9.3mm | Flat |

| MIT-148-204 | Ultra-Small/Small | 0-.25″ .001″ Mechanical Micrometer Head, .25″ Diameter Stem with Clamp Nut, Flat Spindle Face | 0 -.25″ | .001″ | ±5µm | 3.5mm | .25″ | 9.3mm | Flat |

| MIT-148-205 | Ultra-Small/Small | 0-6.5mm, 0.01mm, Mechanical Micrometer Head, Ultra-Small, 6mm Diameter Plain Stem, Spherical (SR3) Spindle Face | 0 – 6.5mm | .01mm | ±5µm | 3.5mm | 6mm | 9.3mm | Flat |

| MIT-148-206 | Ultra-Small/Small | 0-.25″ .001″ Mechanical Micrometer Head, .25″ Diameter Plain Stem, Spherical (SR3) Spindle Face | 0 -.25″ | .001″ | ±5µm | 3.5mm | .25″ | 9.3mm | Flat |

| MIT-148-207 | Ultra-Small/Small | 0-6.5mm, 0.01mm, Mechanical Micrometer Head, Ultra-Small, 6mm Diameter Stem with Clamp Nut, Spherical (SR3) Spindle Face | 0 – 6.5mm | .01mm | ±5µm | 3.5mm | 6mm | 9.3mm | Flat |

| MIT-148-208 | Ultra-Small/Small | 0-.25″ .001″ Mechanical Micrometer Head, .25″ Diameter Stem with Clamp Nut, Spherical (SR3) Spindle Face | 0 -.25″ | .001″ | ±5µm | 3.5mm | .25″ | 9.3mm | Flat |

| MIT-148-210 | Ultra-Small/Small | .25-0″ .001″ Mechanical Micrometer Head, .25″ Diameter Plain Stem, Flat Spindle Face, Reverse Read | .25 – 0″ | .001″ | ±5µm | 3.5mm | .25″ | 9.3mm | Flat |

| MIT-148-212 | Ultra-Small/Small | .25-0″ .001″ Mechanical Micrometer Head, .25″ Diameter Stem with Clamp Nut, Flat Spindle Face, Reverse Read | .25 – 0″ | .001″ | ±5µm | 3.5mm | .25″ | 9.3mm | Flat |

| MIT-148-216 | Ultra-Small/Small | 0-5mm, 0.01mm, Mechanical Micrometer Head, Ultra-Small, 3.5mm Diameter Stem with Clamp Nut, Spherical (SR1.5) Spindle Face | 0 – 5mm | .01mm | ±5µm | 3.5mm | 3.5mm | 6mm | Spherical |

| MIT-148-242 | Fine Spindle Feeding | 0-6.5mm, 0.01mm, Mechanical Micrometer Head, 6mm Diameter Plain Stem, Fine (.01/rev) Spindle Feed, Spherical (SR3) Spindle Face, Small Thimble Diameter | 0 – 6.5mm | .002mm | ±5µm | 6.35mm | 6mm | 15mm | Flat |

| MIT-148-303 | Large Thimble Diameter for Easy Reading | 0-6.5mm, 0.01mm, Mechanical Micrometer Head, 9.5mm Diameter Plain Stem, Flat Spindle Face, Large (20mm) Thimble Diameter | 0 – 6.5mm | .01mm | ±2µm | 6.35mm | 9.5mm | 20mm | Flat |

| MIT-148-351 | Large Thimble Diameter for Easy Reading | 0-.25″ .001″ Mechanical Micrometer Head, .375″ Diameter Plain Stem, Flat Spindle Face, Large (.59 In) Thimble Diameter | 0 – .25″ | .001″ | ±.0001″ | 6.35mm | .375″ | .59″ | Flat |

| MIT-148-352 | Large Thimble Diameter for Easy Reading | 0-.25″ .001″ Mechanical Micrometer Head, .375 InDiameter Stem with Clamp Nut, Flat Spindle Face, Large (.59 In) Thimble Diameter | 0 – .25″ | .001″ | ±.0001″ | 6.35mm | .375″ | .59″ | Flat |

| MIT-148-353 | Large Thimble Diameter for Easy Reading | 0-.25″ .001″ Mechanical Micrometer Head, .375″ Diameter Plain Stem, Flat Spindle Face, Large (.79 In) Thimble Diameter | 0 – .25″ | .001″ | ±.0001″ | 6.35mm | .375″ | .79″ | Flat |

| MIT-148-354 | Large Thimble Diameter for Easy Reading | 0-.25″ .001″ Mechanical Micrometer Head, .375 InDiameter Stem with Clamp Nut, Flat Spindle Face, Large (.79 In) Thimble Diameter | 0 – .25″ | .001″ | ±.0001″ | 6.35mm | .375″ | .79″ | Flat |

| MIT-148-355 | Large Thimble Diameter for Easy Reading | 0-.25″ .001″ Mechanical Micrometer Head, .375″ Diameter Plain Stem, Flat Spindle Face, Large (1.14 In) Thimble Diameter | 0 – .25″ | .001″ | ±.0001″ | 6.35mm | .375″ | 1.14″ | Flat |

| MIT-148-356 | Large Thimble Diameter for Easy Reading | 0-.25″ .001″ Mechanical Micrometer Head, .375″ Diameter Stem with Clamp Nut, Flat Spindle Face, Large (1.14 In) Thimble Diameter | 0 – .25″ | .001″ | ±.0001″ | 6.35mm | .375″ | 1.14″ | Flat |

| MIT-148-357 | Large Thimble Diameter for Easy Reading | 0-.5″ .001″ Mechanical Micrometer Head, .375″ Diameter Plain Stem, Flat Spindle Face, Large (.59 In) Thimble Diameter | 0 – .5″ | .001″ | ±.0001″ | 6.35mm | .375″ | .59″ | Flat |

| MIT-148-358 | Large Thimble Diameter for Easy Reading | 0-.5″ .001″ Mechanical Micrometer Head, .375 InDiameter Stem with Clamp Nut, Flat Spindle Face, Large (.59 In) Thimble Diameter | 0 – .5″ | .001″ | ±.0001″ | 6.35mm | .375″ | .59″ | Flat |

| MIT-148-359 | Large Thimble Diameter for Easy Reading | 0-.5″ .001″ Mechanical Micrometer Head, .375″ Diameter Plain Stem, Flat Spindle Face, Large (.79 In) Thimble Diameter | 0 – .5″ | .001″ | ±.0001″ | 6.35mm | .375″ | .79″ | Flat |

| MIT-148-360 | Large Thimble Diameter for Easy Reading | 0-.5″ .001″ Mechanical Micrometer Head, .375 InDiameter Stem with Clamp Nut, Flat Spindle Face, Large (.79 In) Thimble Diameter | 0 – .5″ | .001″ | ±.0001″ | 6.35mm | .375″ | .79″ | Flat |

| MIT-148-361 | Large Thimble Diameter for Easy Reading | 0-.5″ .001″ Mechanical Micrometer Head, .375″ Diameter Plain Stem, Flat Spindle Face, Large (1.14 In) Thimble Diameter | 0 – .5″ | .001″ | ±.0001″ | 6.35mm | .375″ | 1.14″ | Flat |

| MIT-148-362 | Large Thimble Diameter for Easy Reading | 0-.5″ .001″ Mechanical Micrometer Head, .375″ Diameter Stem with Clamp Nut, Flat Spindle Face, Large (1.14 In) Thimble Diameter | 0 – .5″ | .001″ | ±.0001″ | 6.35mm | .375″ | 1.14″ | Flat |

| MIT-148-501 | Common in small size w/zero adj thimble | 0-.5″ .001″ Mechanical Micrometer Head, .375″ Diameter Plain Stem, Flat Spindle Face, Zero-Adjust Thimble | 0 – .5″ | .001″ | ±.0001″ | 5mm | .375″ | 13mm | Flat |

| Gagemaker Model | Product Type | Description | Resolution | Accuracy | Length | Thread Angle | Angle Accuracy |

|---|---|---|---|---|---|---|---|

| MIT-167-132 | Micrometer Standard | 800mm, Micrometer Standard bar, 11.9mm Diameter | – | ±17µm | 1″ | – | – |

| MIT-167-141 | Micrometer Standard | 1″, Micrometer Standard Bar, .25″ Diameter | – | ±.000005″ | 1″ | – | – |

| MIT-167-142 | Micrometer Standard | 2″, Micrometer Standard Bar, .25″ Diameter | – | ±.0001″ | 2″ | – | – |

| MIT-167-143 | Micrometer Standard | 3″, Micrometer Standard Bar, .25″ Diameter | – | ±.0001″ | 3″ | – | – |

| MIT-167-144 | Micrometer Standard | 4″, Micrometer Standard Bar, .31″ Diameter | – | ±.0001″ | 4″ | – | – |

| MIT-167-145 | Micrometer Standard | 5″, Micrometer Standard Bar, .31″ Diameter | – | ±.00015″ | 5″ | – | – |

| MIT-167-146 | Micrometer Standard | 6″, Micrometer Standard Bar, .31″ Diameter | – | ±.00015″ | 6″ | – | – |

| MIT-167-147 | Micrometer Standard | 7″, Micrometer Standard Bar, .31″ Diameter | – | ±.00015″ | 7″ | – | – |

| MIT-167-148 | Micrometer Standard | 8″, Micrometer Standard Bar, .37″ Diameter | – | ±.00015″ | 8″ | – | – |

| MIT-167-149 | Micrometer Standard | 9″, Micrometer Standard Bar, .37″ Diameter | – | ±.0002″ | 9″ | – | – |

Optical Measurement

Gagemaker offers two types of Mitutoyo Optical Measurement devices:

- Microscopes: Toolmaker’s microscopes and measuring microscopes differ from standard microscopes in one unique way–their ability to measure via a movable microstage, which allows the workpiece to be moved under the optics system. A measuring device (mike heads or DRO system) can measure the microstage travel while the operator moves the workpiece below a crosshair in the optics system from one feature to another. The Mitutoyo toolmaker’s microscope also has a built-in protractor for measuring feature angles. Measuring microscopes are the big brother of toolmaker’s microscopes. They generally have larger stages and options for video systems.

- Profile Projectors: Also called optical comparators or shadowgraphs, profile projectors come in two basic types with many variations of each type. The first and most widely used in industry is the horizontal model. The second is the vertical model. Each type has advantages and disadvantages. Profile projectors are available from small bench-top models to larger units that can be closet size.

| Gagemaker Model | Description |

|---|---|

| MIT-176-808A | TM-505 Toolmaker’s Microscope, 30X Magnification, 2″ X 2″ Stage Travel, With Digimatic Mic Heads |

| MIT-176-809A | TM-510 Toolmaker’s Microscope, 30X Magnification, 4″ X 2″ Stage Travel, With Digimatic Mic Heads |

| MIT-176-811A | TM-505 Toolmaker’s Microscope, 30X Magnification, 2″ X 2″ Stage Travel |

| MIT-176-812A | TM-510 Toolmaker’s Microscope, 30X Magnification, 4″ X 2″ Stage Travel |

| Gagemaker Model | Product Type | Description |

|---|---|---|

| MIT-172-142 | Workpiece Fixture | Center Support for Profile Projector 120mm Maximum Workpiece Height |

| MIT-172-144 | Workpiece Fixture | Rotary Vise for Profile Projector 60mm Maximum Workpiece Height and 40mm Jaw Width |

| MIT-172-810-10A | Profile Projector | .0001″/0.001mm, PH-A14, Inverted Image Horizontal Profile Projector, 14 In Screen, 10x lens, Counter and Stand Not Included |

| MIT-264-156A | Data Processing Unit | QM-Data200, Data Processing Unit, 2-D Geometry Measurement Capabilities, Color LCD Display, USB Memory, CSV Output, Arm Mount Type for Profile Projectors |

| MIT-64AAA129B | Stand | Machine Stand for PH-A14 |

| MIT-64AAB149 | Counter | Counter Tray for KA Counter Used With PH-A14/PH-3515F |

Other Small Tools

Gagemaker offers a large assortment of other Mitutoyo small tools like micrometer stands, hand tachometers, combination squares, pitch gages, pocket comparators, telescoping gages, steel rules, protractors, wigglers, scribers, and much more.

| Gagemaker Model | Product Group | Product Type | Specialty | Description | IND. OR SET | Pieces Per Set | Range | Resolution | Accuracy | Length | Width |

|---|---|---|---|---|---|---|---|---|---|---|---|

| MIT-050101 | Inch | Edge and Center Finder | Edge Type | Edge Finder, Center Type, .375″Shank, .2″Tip | Individual | – | – | – | – | – | – |

| MIT-050102 | Inch | Edge and Center Finder | Edge Type | 1/2″Shank, Edge Finder, .5″Shank Diameter, .2″Tip Diameter, Hardened | Individual | – | – | – | – | – | – |

| MIT-50104 | Inch | Edge and Center Finder | Center Type | Edge Finder, Center Type, .5″Shank, .2″Tip | Individual | – | – | – | – | – | – |

| MIT-50109 | Inch | Edge and Center Finder | Edge Type | Edge Finder, Edge Type, .5″Shank, .2″Tip | Individual | – | – | – | – | – | – |

| MIT-50110 | Inch | Edge and Center Finder | Double Edge Finder | Edge Finder, Double Edge, .5″Shank, .2″/.5″Tip | Individual | – | – | – | – | – | – |

| MIT-101461 | Anvil | Indicator Stand | Hardend Steel, Flat | Flat Anvil, For”dicator Stands, Hardened Steel | Individual | – | – | – | – | – | – |

| MIT-050083-10 | Other Fixtures | Depth Base Attachment | 4-8 In and 100-200mm Calipers | 3″/75mm, Caliper Depth Base Attachment, (For 4, 6, 8″/100, 150, 200mm Vernier, Dial and Digital Calipers with Depth Measuring Bar) | Individual | – | – | – | – | 3″/75mm | – |

| MIT-050084-10 | Other Fixtures | Depth Base Attachment | 4-8 In and 100-200mm Calipers | 4″/100mm, Caliper Depth Base Attachment, (For 4, 6, 8″/100, 150, 200mm Vernier, Dial and Digital Calipers with Depth Measuring Bar) | Individual | – | – | – | – | 4″/100mm | – |

| MIT-050085-10 | Other Fixtures | Depth Base Attachment | 12 In and 300mm Calipers | 5″/125mm, Caliper Depth Base Attachment, (For 12″/300mm Vernier, Dial and Digital Calipers with Depth Measuring Bar) | Individual | – | – | – | – | 5″/125mm | – |

| MIT-154-901 | Small Hole Gage Set | Small Hole ID | .125-.5″, Small Hole Gage Set, 4 Pieces (.125-.2″, .2-.3″, .3-.4″, .4-.5″) | Set | 4 | .125 – .5″ | Variable | – | Varied | – | |